The Responsible Engineer

The ownership culture behind SpaceX’s rapid development, and how hardware startups can apply it.

TL;DR: In startups chasing faster development, there is plenty of folklore about velocity, vertical integration, long hours, decisive CEOs, and big fundraising. But what truly enables high-velocity execution? We look at the engineering ethos behind a company whose culture has been studied, mythologized, and imitated across the industry: SpaceX. At its core is the concept of the Responsible Engineer: a framework where one owner is accountable for an outcome rather than a task list, and has the authority to make the decisions that turn it into reality. Without this ground-up mentality of true responsibility and extreme ownership, rapid development will always struggle.

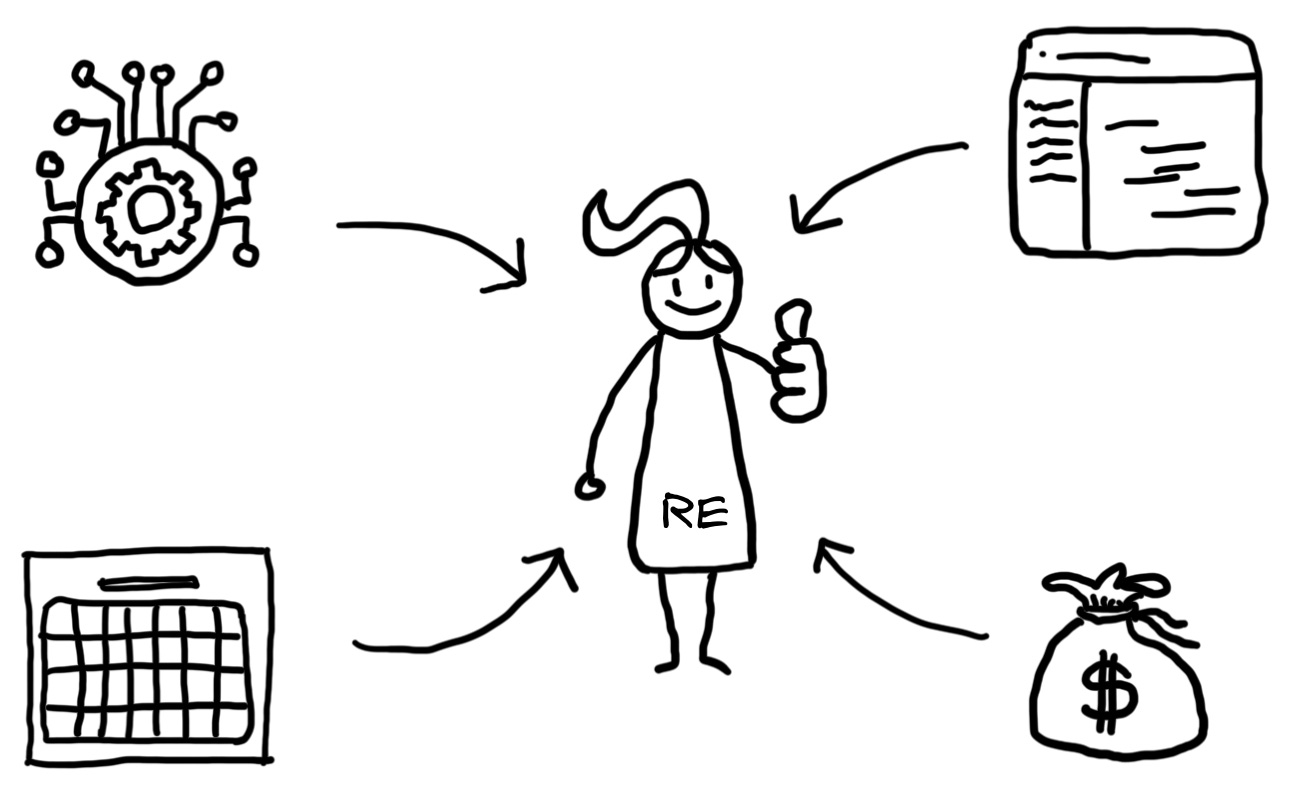

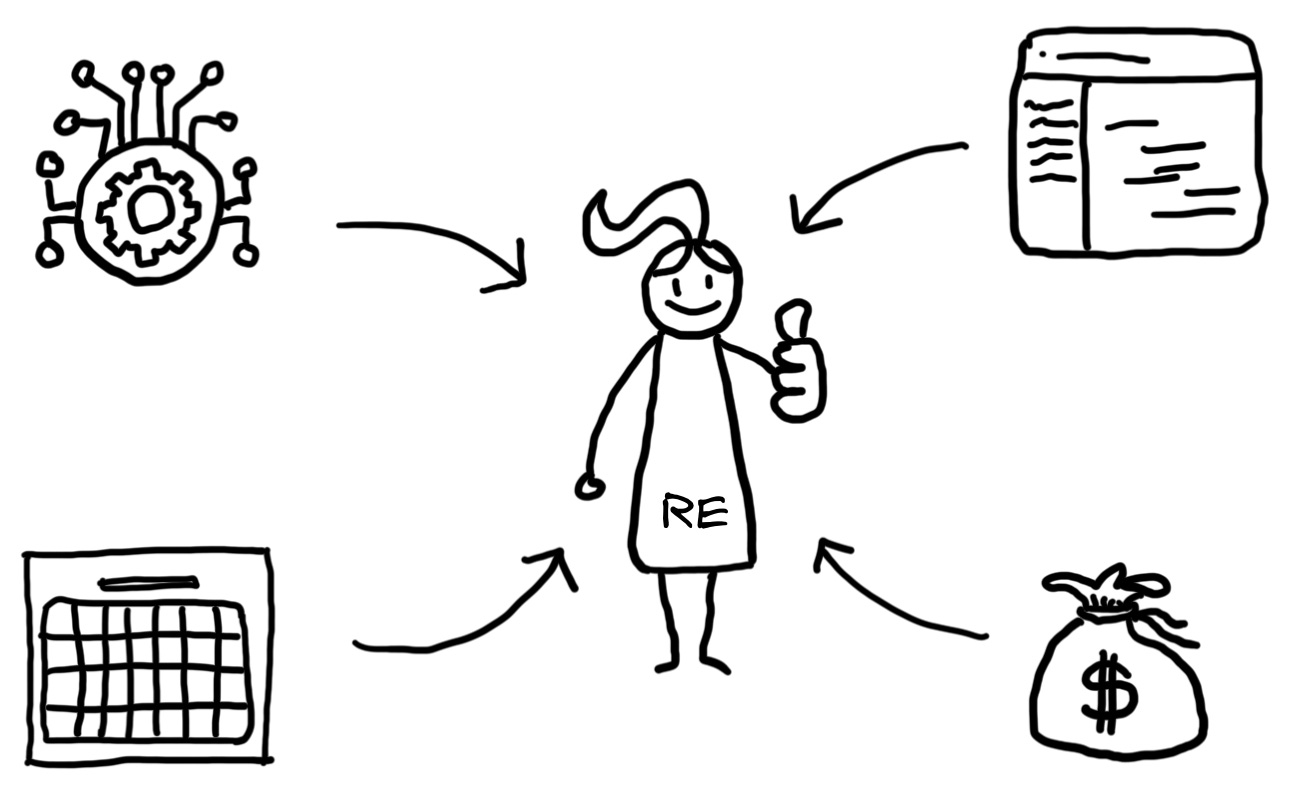

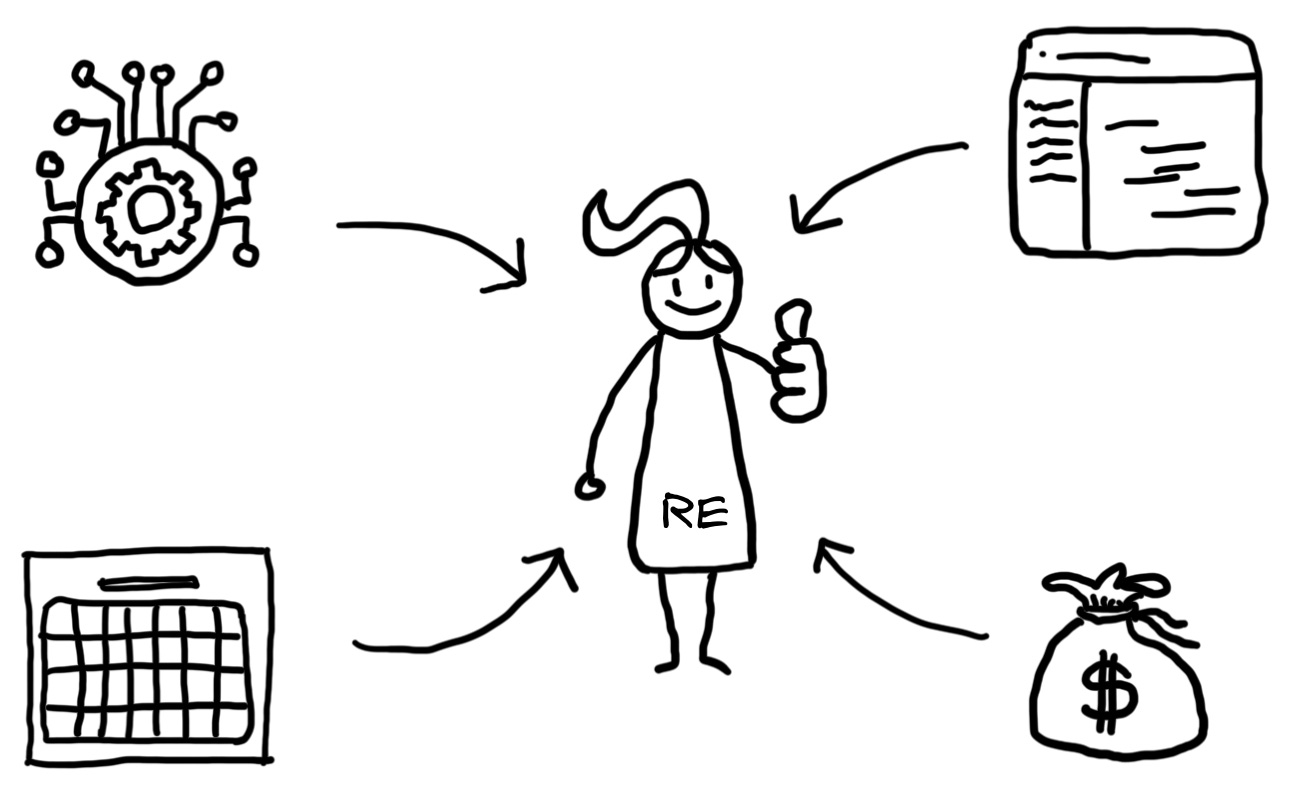

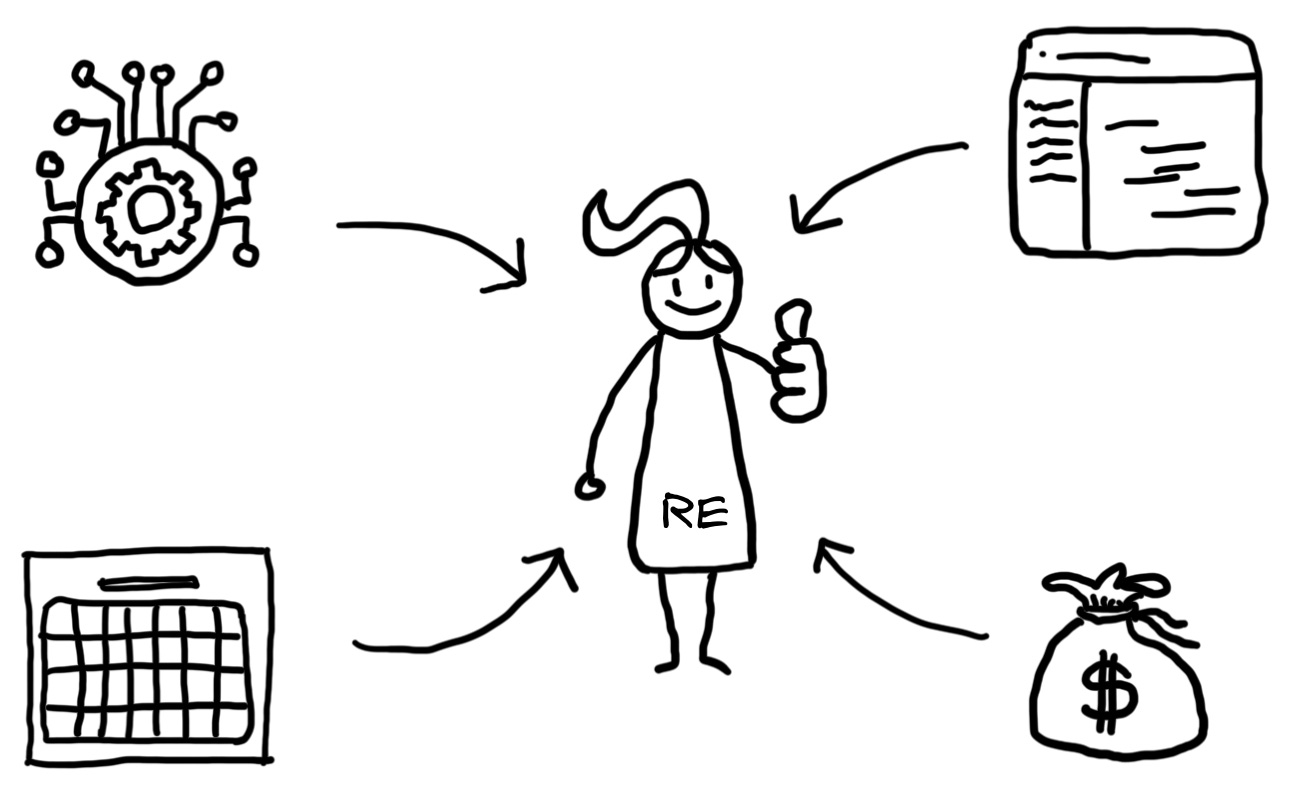

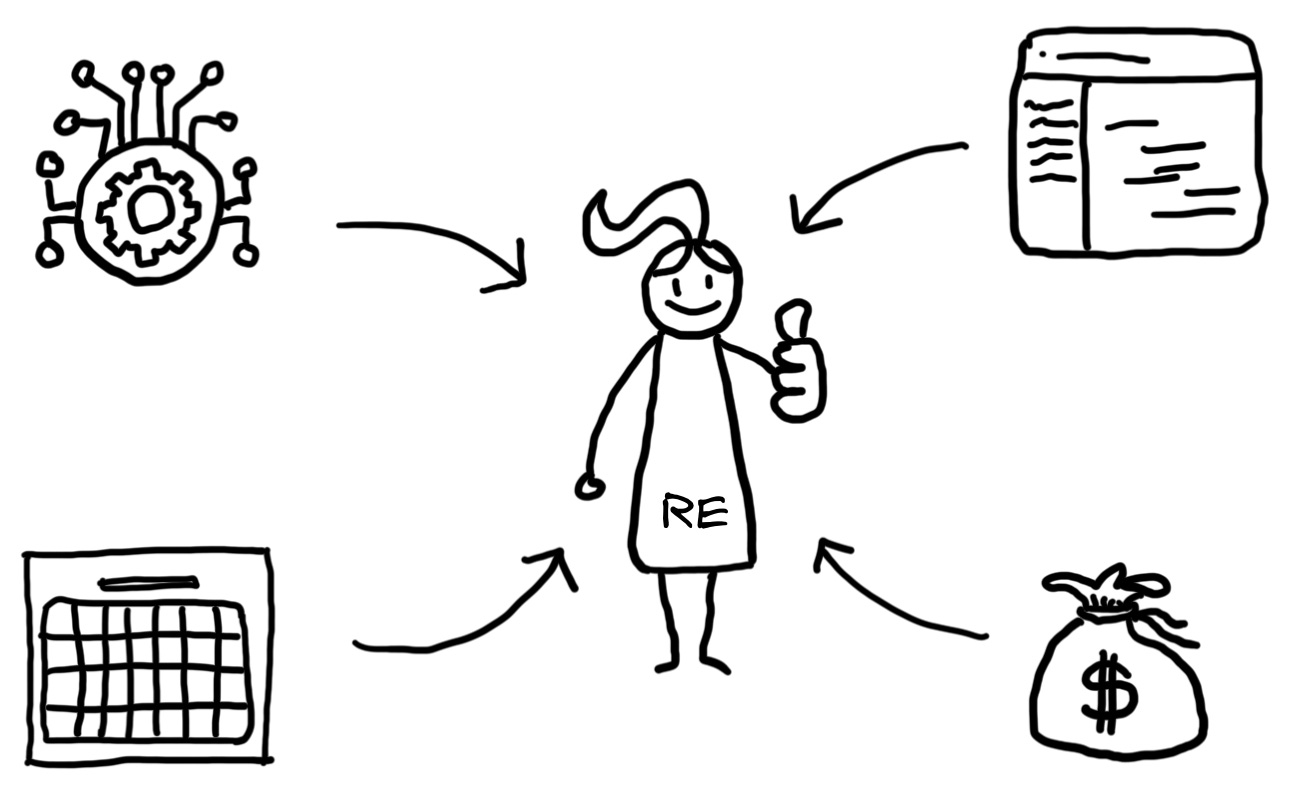

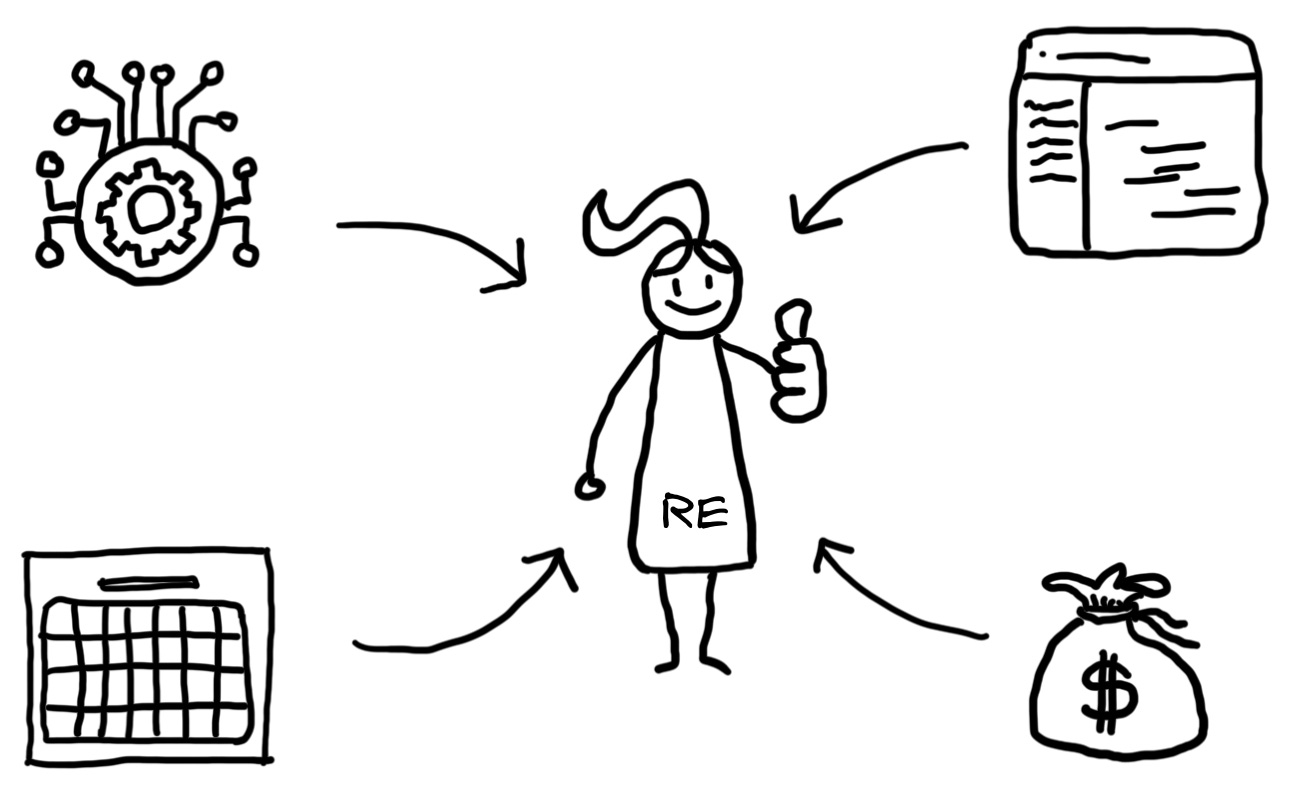

The Responsible Engineer (RE) is responsible for an outcome. This means wearing many hats to get there.

Let’s talk about “Responsibility”

When leading teams, there is always talk about accountability and responsibility. In big companies, the RACI chart is the common language. One person is Responsible, another is Accountable, many are Consulted, and many are Informed. In practice the weight often shifts to the C and the I, which slows decisions and thins real ownership. Most of the time, unless you’re referring to V.P. level leadership, people talk about responsibility as the responsibility to accomplish a set of tasks and not the responsibility of delivering an outcome.

Take a more traditional aerospace organization example: A systems engineer might be responsible for establishing the requirements for a component, a domain specific engineer might be responsible for providing the overall design, a designer might responsible for the final CAD, an analyst responsible for providing margins, a scheduler might be responsible for the schedule, a program manager responsible for tracking costs and progress, a manufacturing engineer responsible for fabrication, and a test engineer responsible for validating the part. Maybe that’s a bit extreme, but I’m sure you have all seen similar scenarios. But who is accountable? “Responsibility” has been reduced to the narrow definition of “who completed the task”1. The why, how, and when something is done is delegated to others.

This engineering operational paradigm has seen humanity accomplish amazing engineering feats like landing rovers on Mars, putting the International Space Station in orbit, and flying the behemoth Airbus A380 passenger jet across the Atlantic. Operating like this also offers a certain organizational robustness to personnel risk, as losing a single person in that chain of responsibilities is unlikely to derail a program. Engineers are more replaceable when they take on bite-sized task-based “responsibilities.”

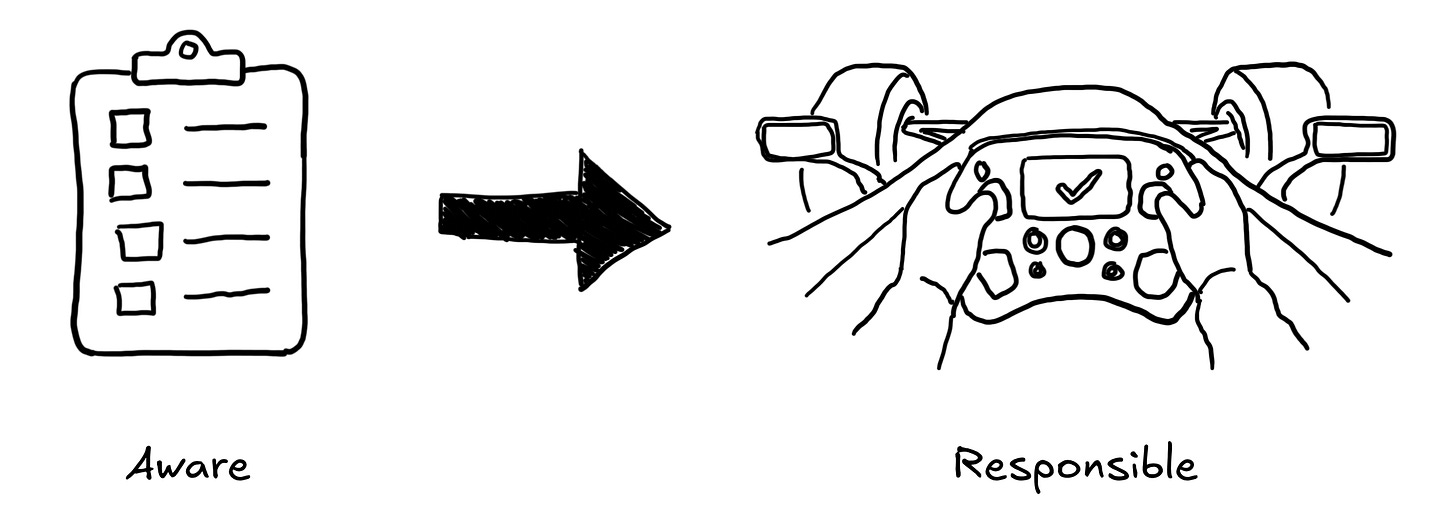

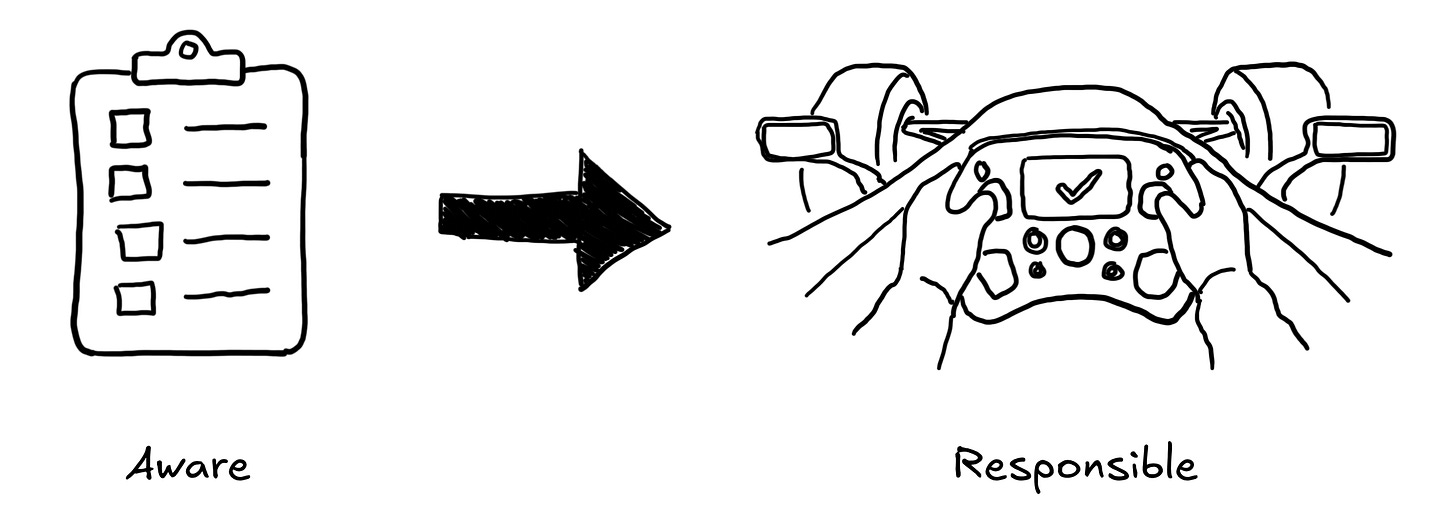

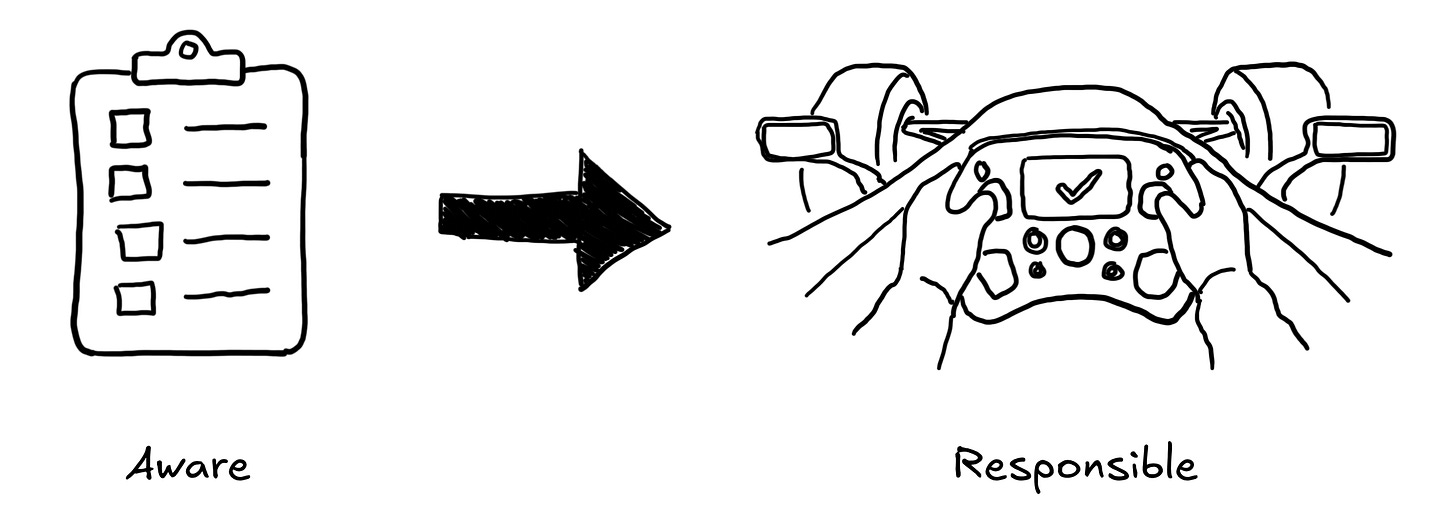

But this approach is not without its downsides, especially when operating in a startup environment. The number of people increases, communication is slower, objectives become obfuscated, and decisions are harder to make. But most importantly, where does the ownership lie? Who is ultimately responsible for the success of the component and how that component plays into the success of the overall project, mission or company? Engineers operating in this paradigm are often aware of outcomes, but not responsible for them.

Startups are forced to establish product market fit, demonstrate viability, and beat the incumbents all before their cash runs out. And here’s where the strength of the Responsible Engineer (RE) mindset comes into play.

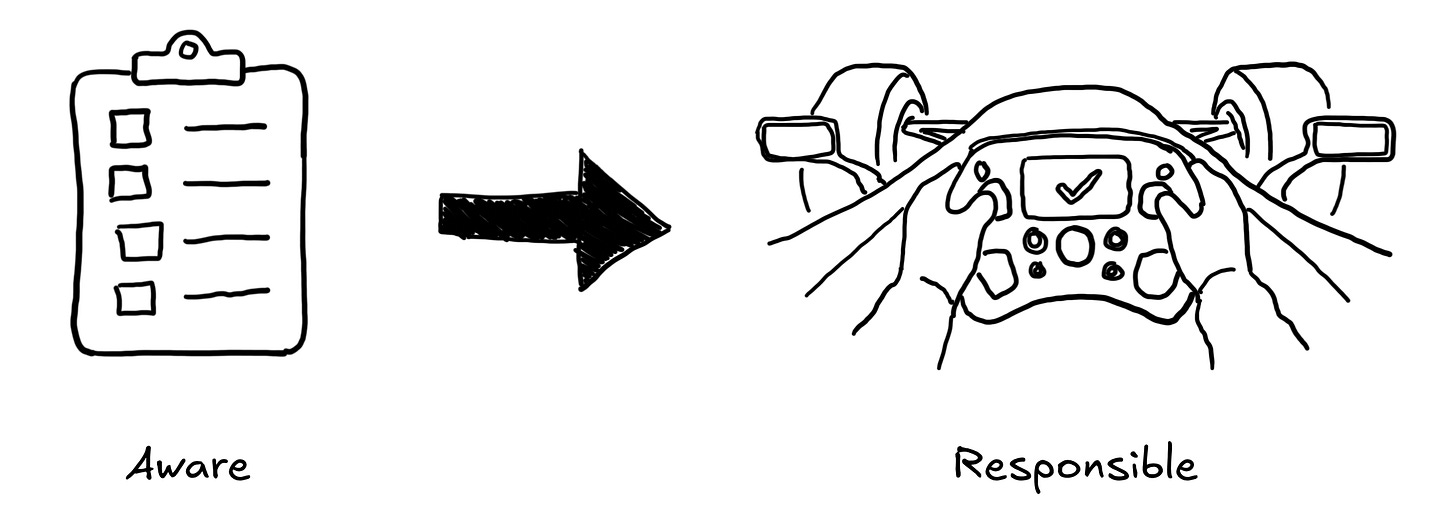

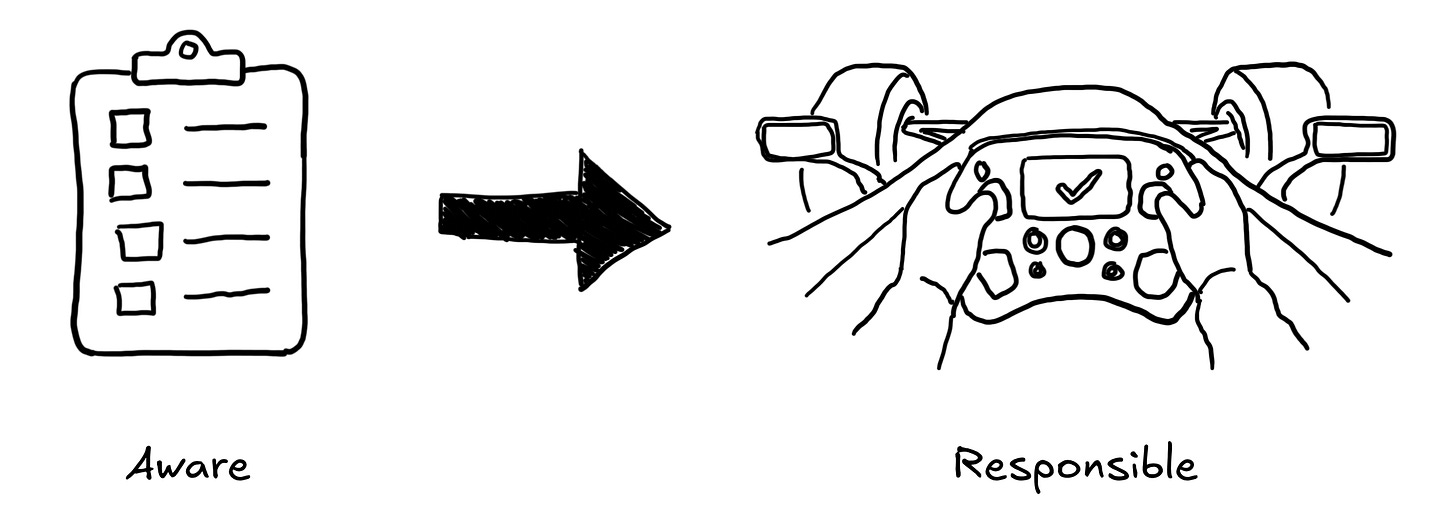

Getting through tasks or taking the wheel.

When we talk about the Responsible Engineer, what we’re really talking about is ownership.

The Responsible Engineer (or RE) framework is one employed religiously at SpaceX. It is the core operating system that allowed a relatively small, scrappy team to build and fly rockets and spacecraft faster than anyone thought possible. It’s hard-wired into the culture, even to this day.

What outcome does your hardware or software provide? You own making the required functionality work. You own schedule. You own the resources you need. You own your interfaces. You own requirements for yourself and for partners. You own your budget. As an RE you are a mini systems engineer, an analyst, a designer, a test lead, and a program manager. In the RACI parlance, “ownership” is the combination of R&A. RE’s own their outcomes.

Depending on the scope, you will get support, and you might even lead a team. But the ultimate responsibility for success and the definition of success sit with a single person. And you have sufficient agency to make the decisions that need to be made.

When responsibility is clear and consolidated, things move faster. Incentives line up because instead of trying to complete your task, you’re trying to make the decision that results in the best overall outcome. People know who handles what, and blockers get chased because they are not someone else’s problem. Designs can iterate quicker because information flows sideways through the company in real time, not up a ladder and back down through many hands.

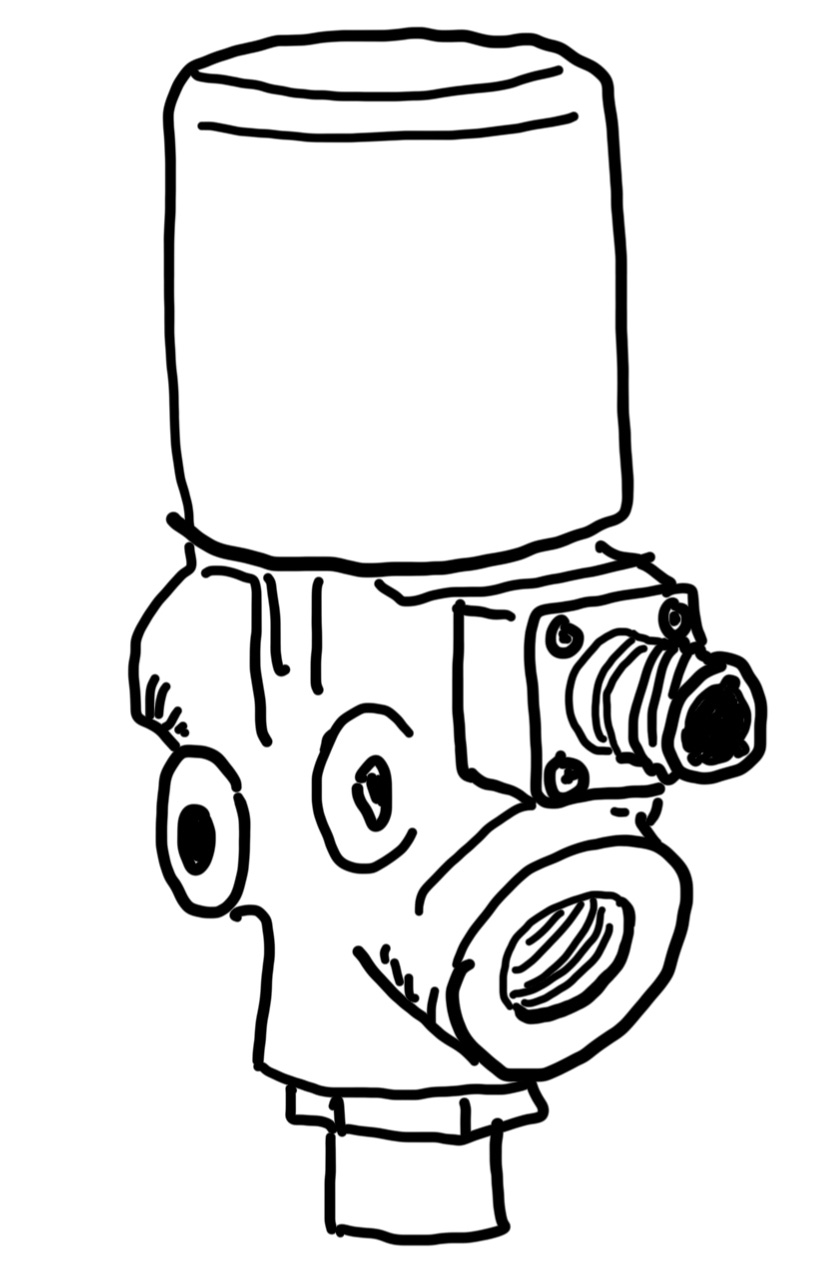

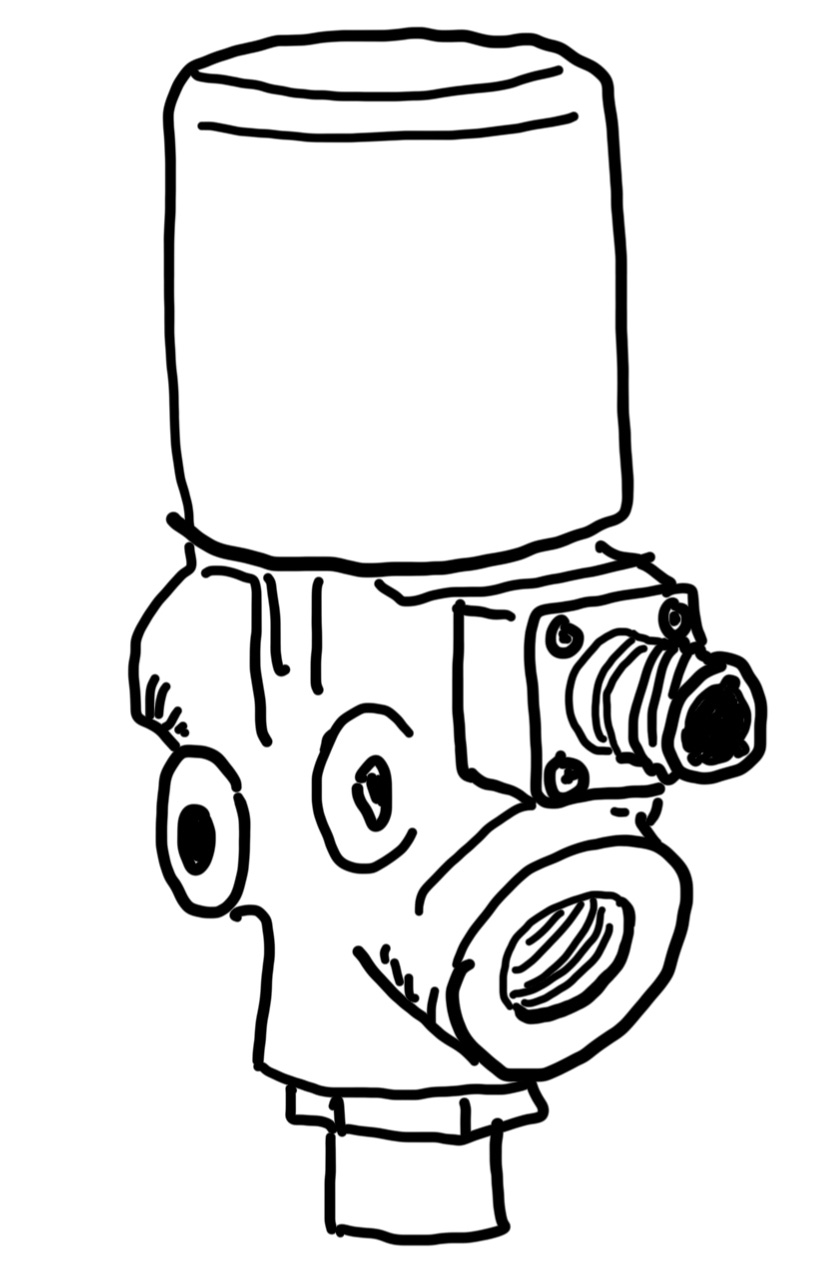

Example: the design cycle for a valve

As mentioned before, in a traditional setup you might have a systems engineer who gathers inputs and writes a spec, a mechanical engineer who designs, a designer who drafts, a stress analyst who produces margins, a manufacturing engineer who places orders, a test engineer who runs development testing, and a program manager who watches schedule and cost. They are all capable, but each carries a narrow view and very little accountability for the full outcome. The program manager is asked to deliver the valve yet is 100% reliant on what everyone else reports.

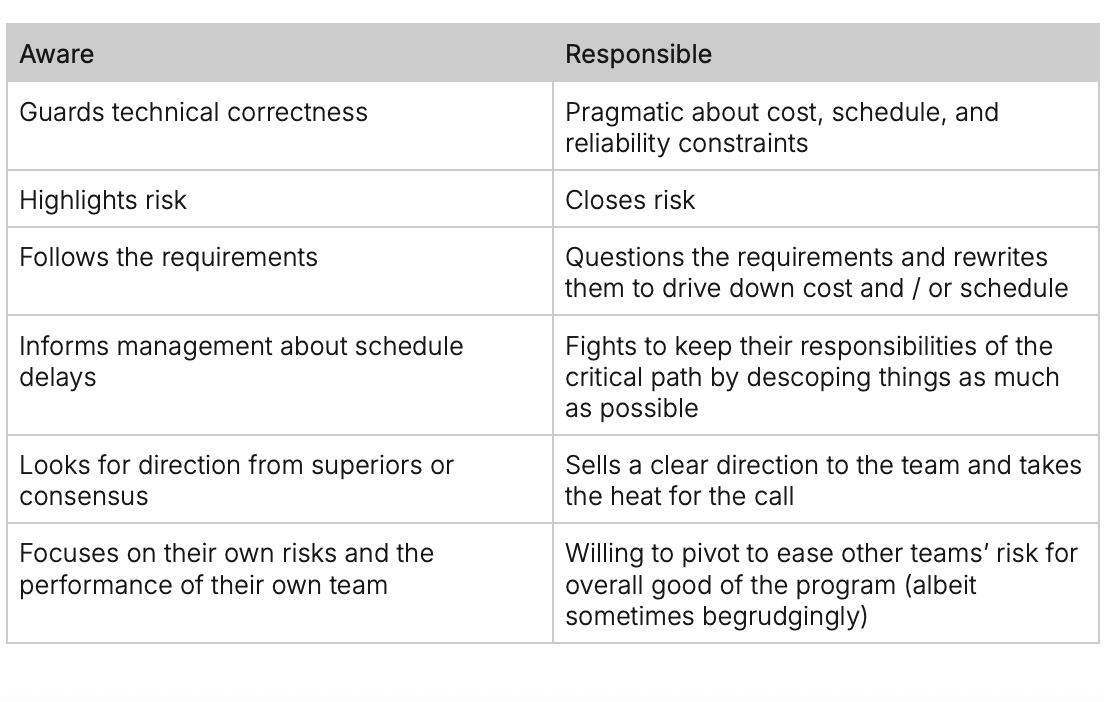

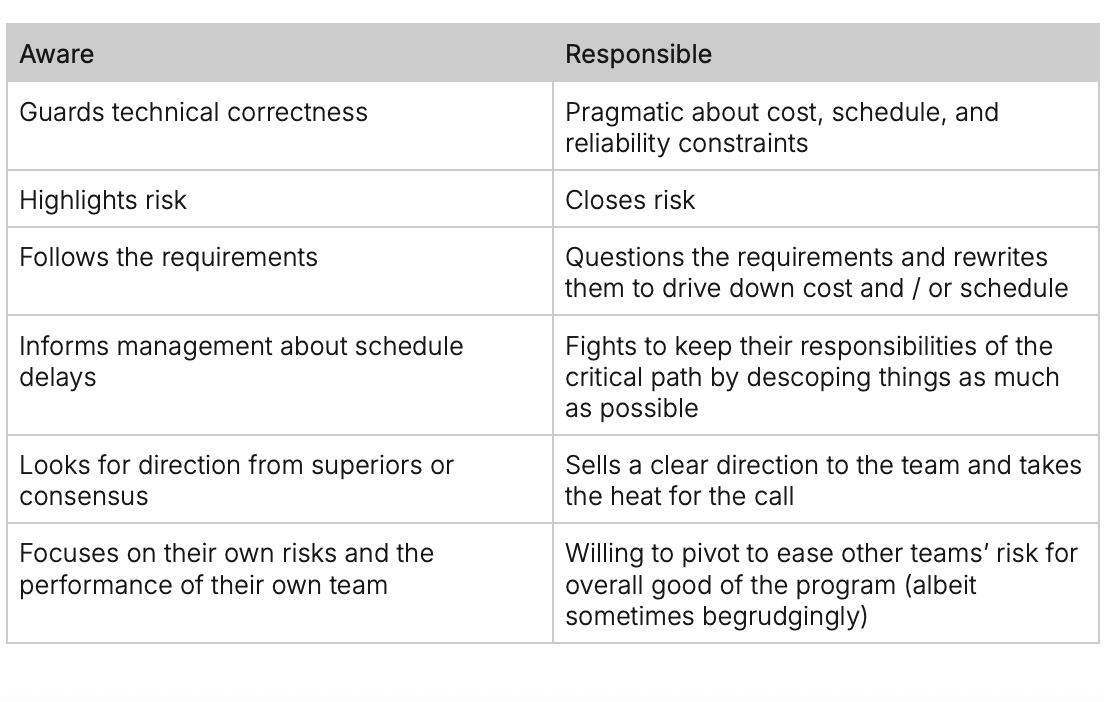

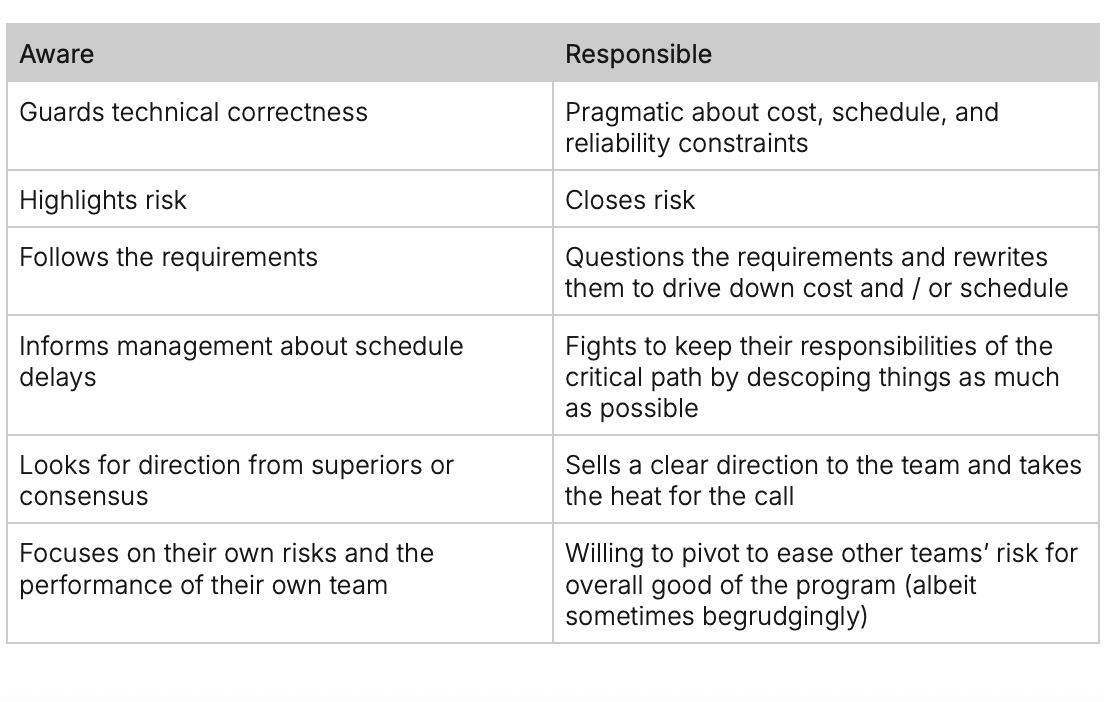

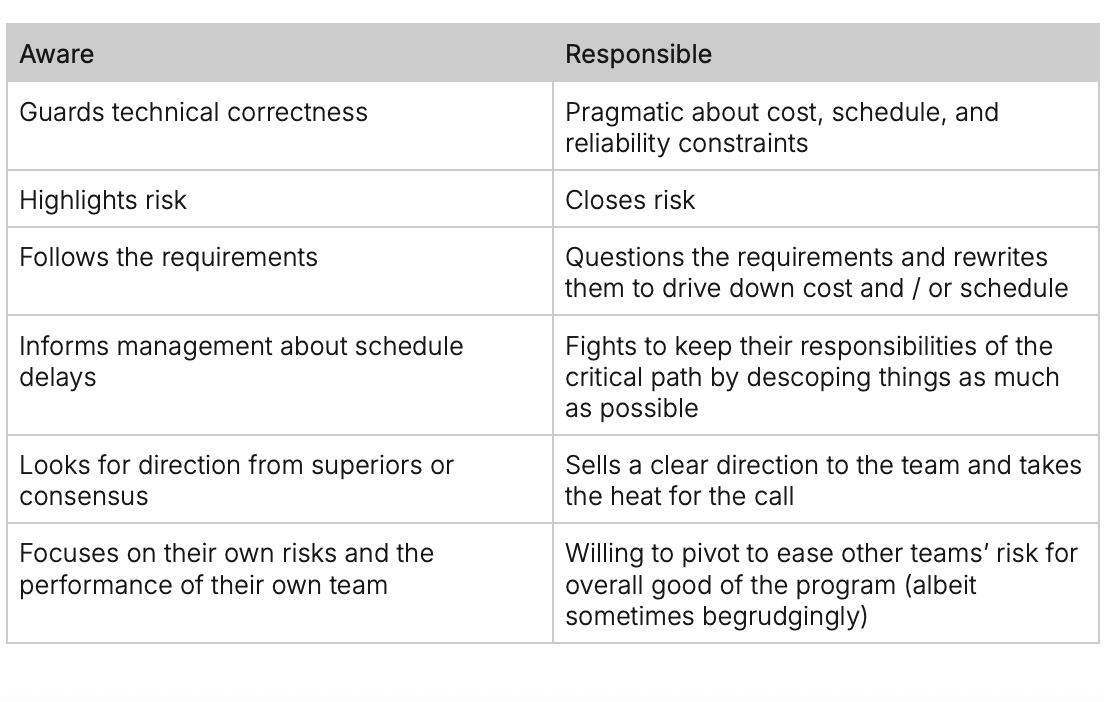

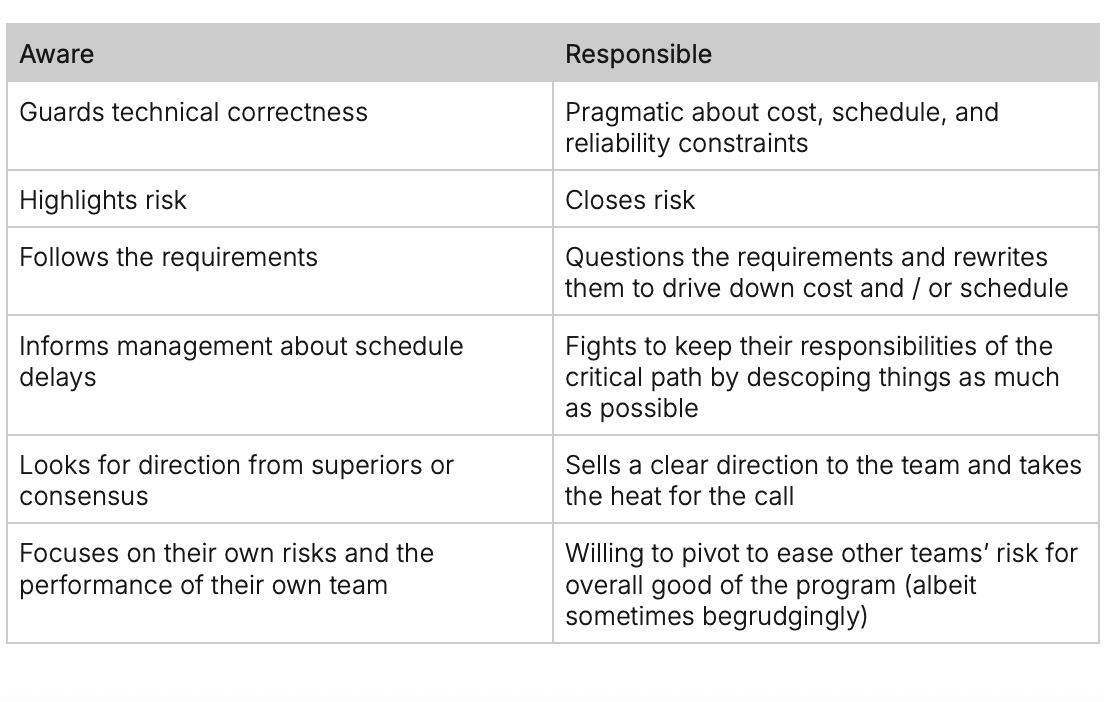

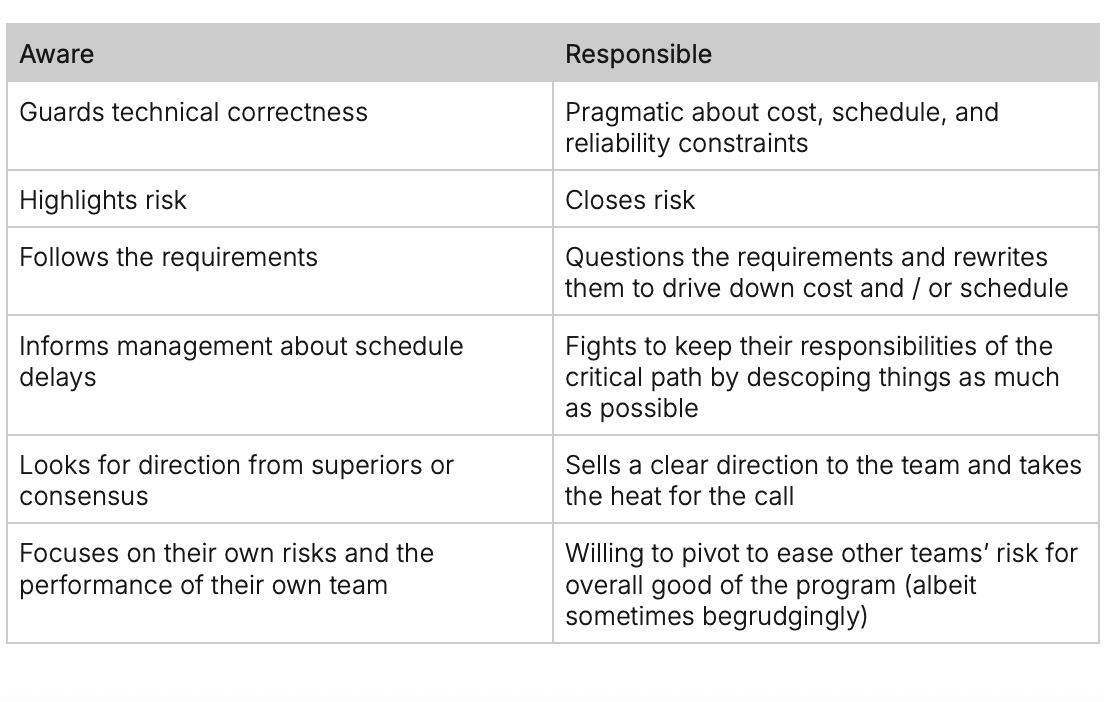

Let’s compare how operating with the RE mindset might be different than the Aware Engineer mindset.

A valve… the bane of all space programs

Technical correctness versus pragmatism

The Aware Engineer might be given a swath of conservative requirements from the systems engineer, and so they start sourcing a flight-qualified solenoid actuator from a top-tier vendor. It's rated for deep space, has perfect documentation, and meets every heritage requirement. It’s the safe, technically correct choice. But it comes with a 40-week lead time and a big price tag, and it’s nearly impossible to tweak once it’s ordered.

Now let’s put on the RE hat. Their job is to deliver a working valve, fast. Because they understand how the valve is used in the system, they know the actuator only needs to fire a handful of times. They understand the thermal margins, the limited duty cycle, and the fact that they can validate performance through direct testing. So they find a small domestic coil shop that’s never flown in space but can build to spec and deliver in three weeks. The potting material the shop usually uses needs to be changed to something more space-worthy, but they are happy to give it a go. It’s not textbook perfect, but it’s testable, it’s cheap, and it gets hardware on the bench fast.

Highlighting risk vs. closing risk

The latest round of analysis leading up to a critical test show vibration levels higher than before. The Aware Engineer, sees this and is concerned that it might cause the valve to chatter, putting the mission at risk during this time. The risk is logged and tracked. Everyone waits for a review to decide what to do next.

With the RE hat on, the engineer goes and talks to the dynamics team. Are they sure this is right? Is there anything that can be done to sharpen the pencil and bring down the predicted levels? Unfortunately, they strike out, no luck there, and the levels are the best they have. There’s no time to redesign anything. They know they are delivering the outcome of a successful flight, not just a component. So they talk to the software person who has been handling the actuation of the valve, and agree on a simple re-assert strategy that continually commands the valve open during this short high vibe period. The risk is logged and tracked, but the mitigation is now done, so it’s closed and accepted.

Broadcasting schedule delays vs. managing schedule delays and challenging requirements.

Now the valve is four weeks late and pushing the whole program. A set of meetings appears. What can we do? The manufacturing engineer calls other shops. Lead times match or get worse. The test engineer is asked to shorten the test cycle. They shave a week, maybe. In truth, the schedule was already optimistic, and the change is just schedule accordion. Time compresses on paper and then springs back in reality. In the end, the program slips.

No single person had both the incentive and the cross-functional knowledge to bring the valve back on track. Responsibility was diffuse and incentives misaligned. A real solution was never likely.

As a RE, the owner has been talking with the machine shop about their schedule. Because they have an end-to-end view, the authority to act, and a real incentive to finish on time, they see the real driver. The leak rate target forced a tolerance that only a specialty shop could hold, which blew out lead time. They call the engineer who owns the interface that pushed the leak rate target. That engineer admits there is some pocket margin they can give back and open up the requirement a bit. With that, the engineer loosens a tolerance, moves the work to a faster shop, and pulls in the date. It takes two conversations and one decision.

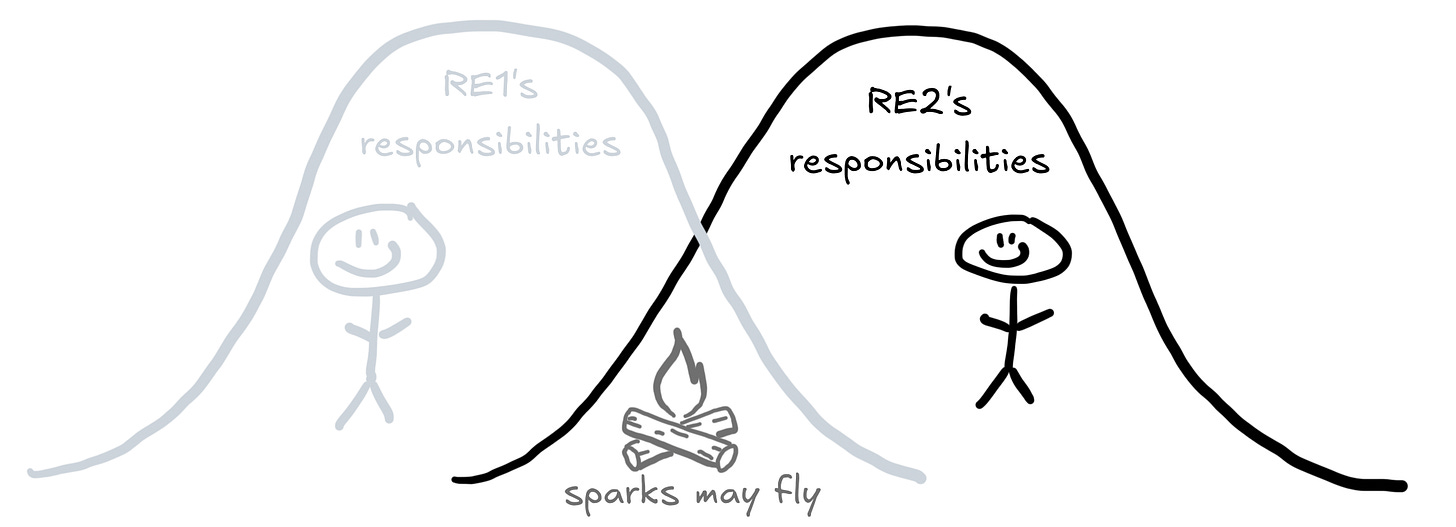

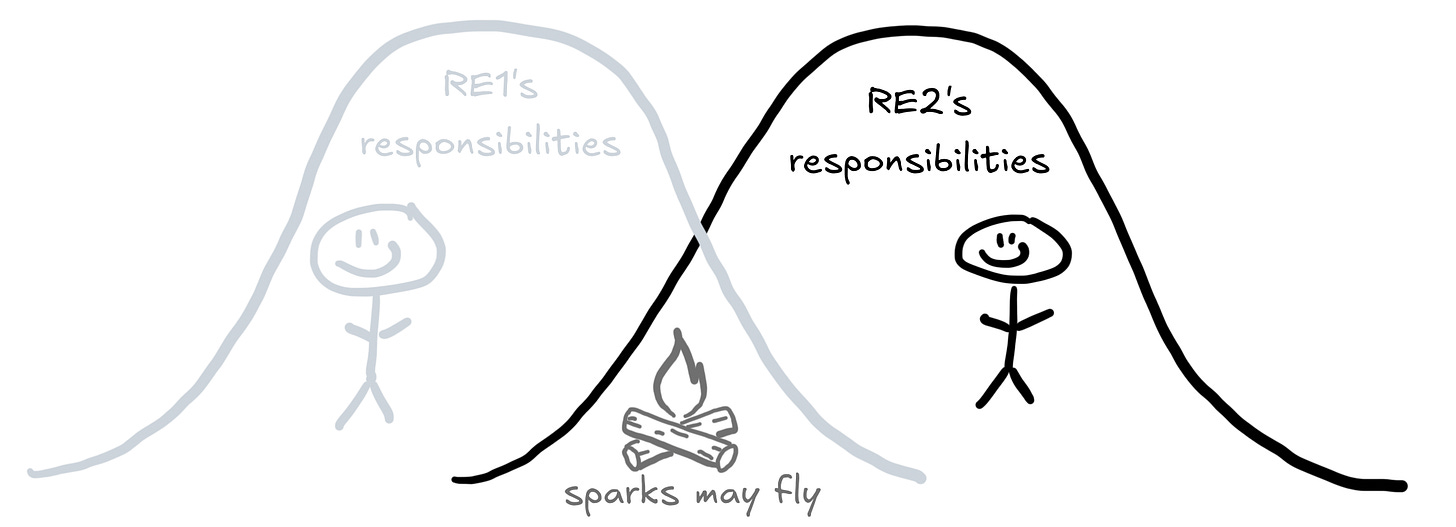

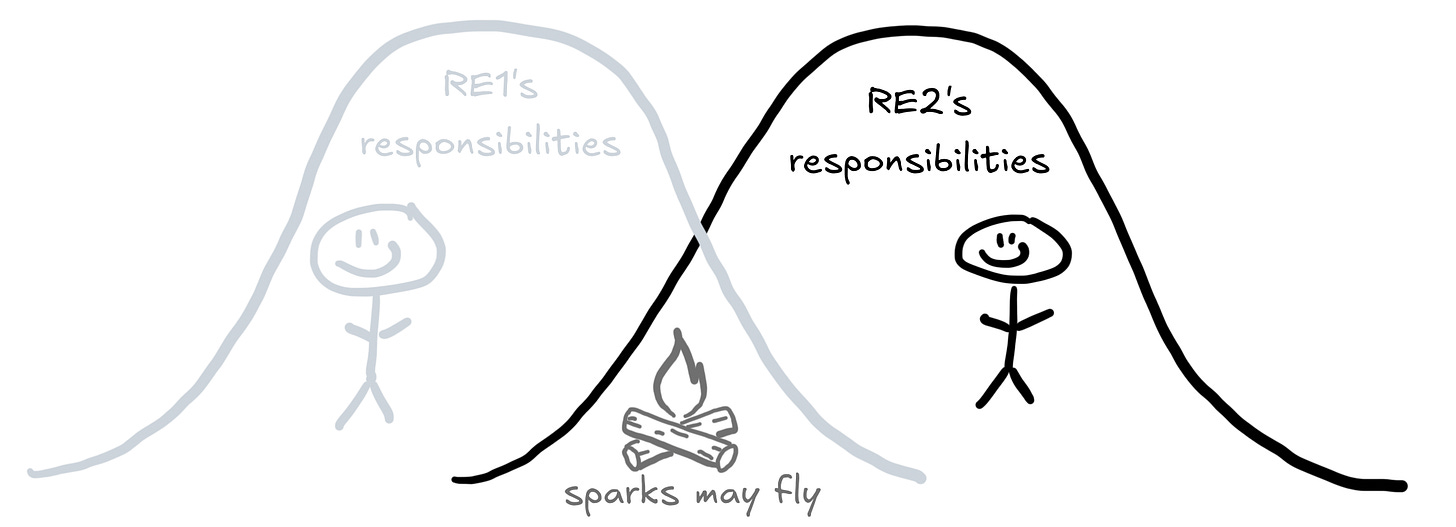

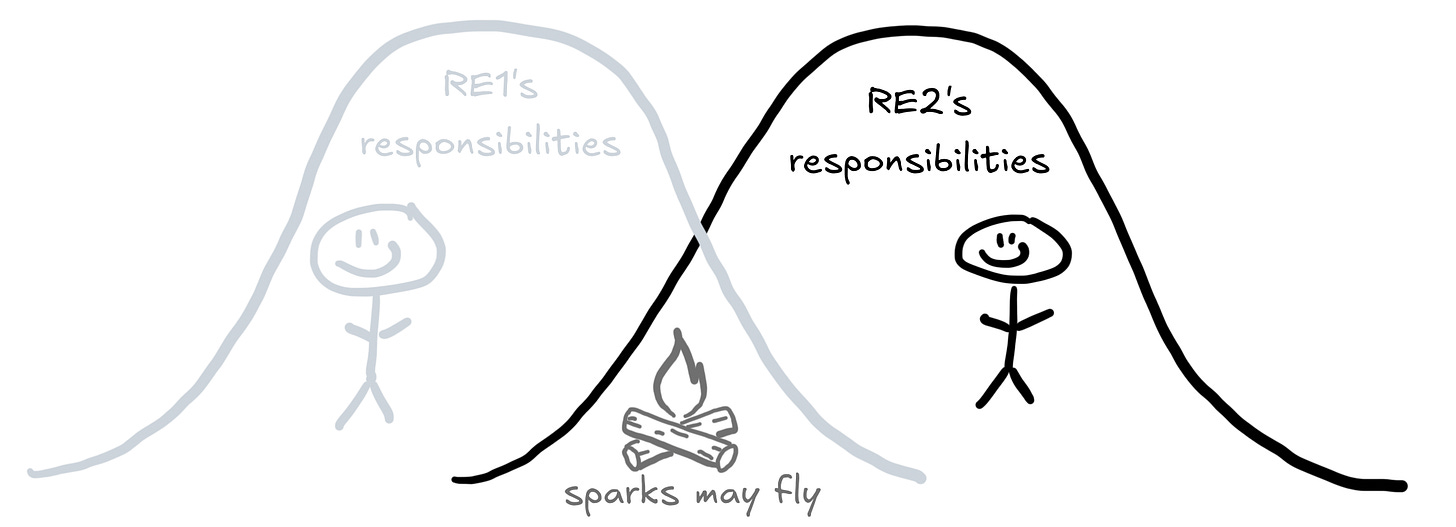

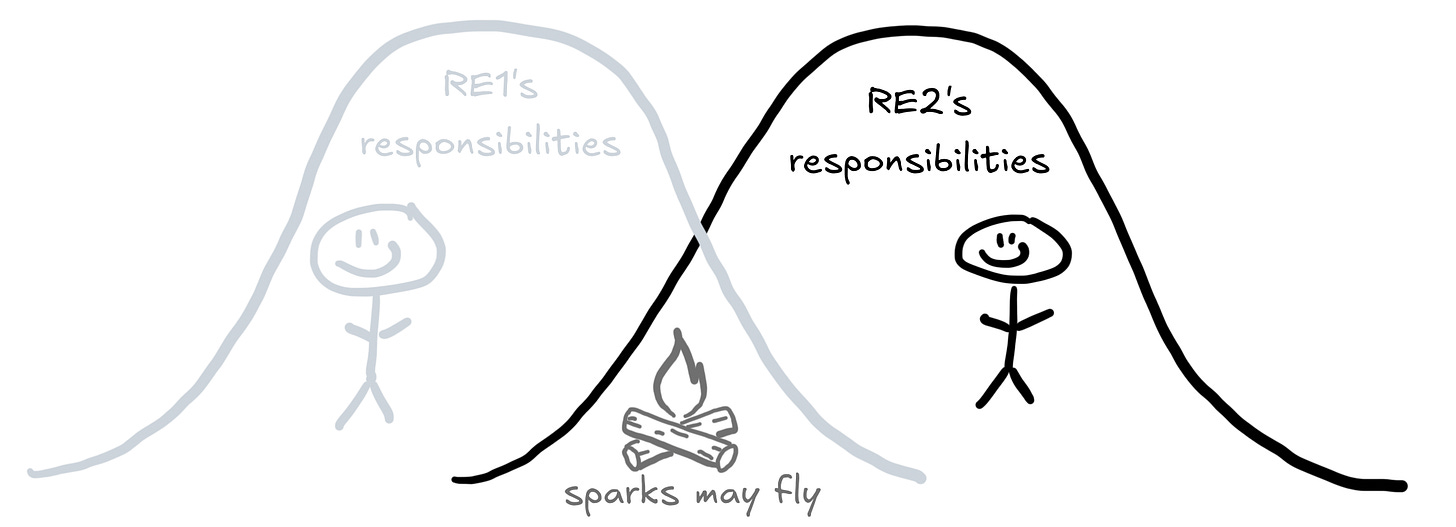

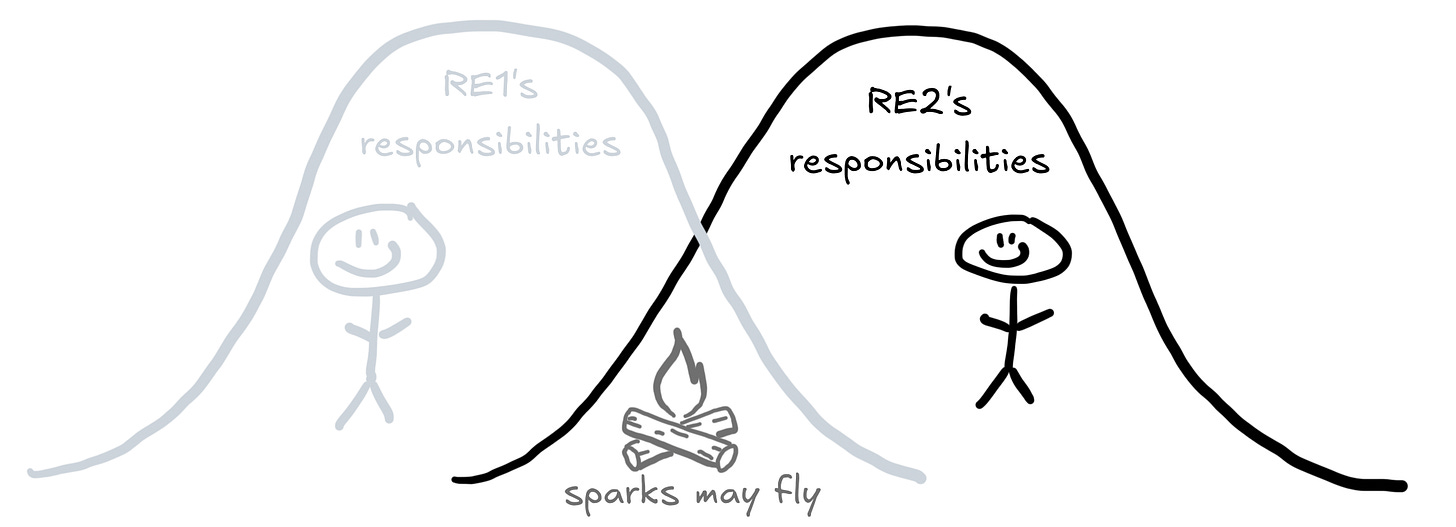

Responsibilities are more like gaussian curves than rectangular functions. Overlap is part of the operating paradigm.

But wait — it can’t all be good, right?

In a traditional organization, when responsibilities overlap, teams lean on role boundaries and formal escalation. That keeps order, yet it often adds delay. Conflicts simmer until program reviews, things are ignored as being “not my problem,” and people hedge designs to protect their function. Junior engineers stay in their swim lanes and do not get chances to build the judgment the company needs.

A team operating with the Responsible mindset can feel like the inmates are running the asylum. Responsibilities will overlap. Some overlaps resolve quickly, some need mediation, and some can turn toxic. Without task boundaries, an engineer can head down the wrong path or over-optimize for a self-serving design.

This is where strong leadership matters. Running a team of REs is not set and forget. Leaders have to trust their engineers and accept that there will be friction and mistakes. They clarify direction and why it matters, and they provide the scaffolding for sound decisions. They unblock when needed and let teams work it out everywhere else. They need to have earned the trust of their engineers by being the fastest fair escalation path, making crisp calls, taking the heat, and giving credit down, so engineers come to them when an issue is intractable or crosses a threshold and needs a quick decision.

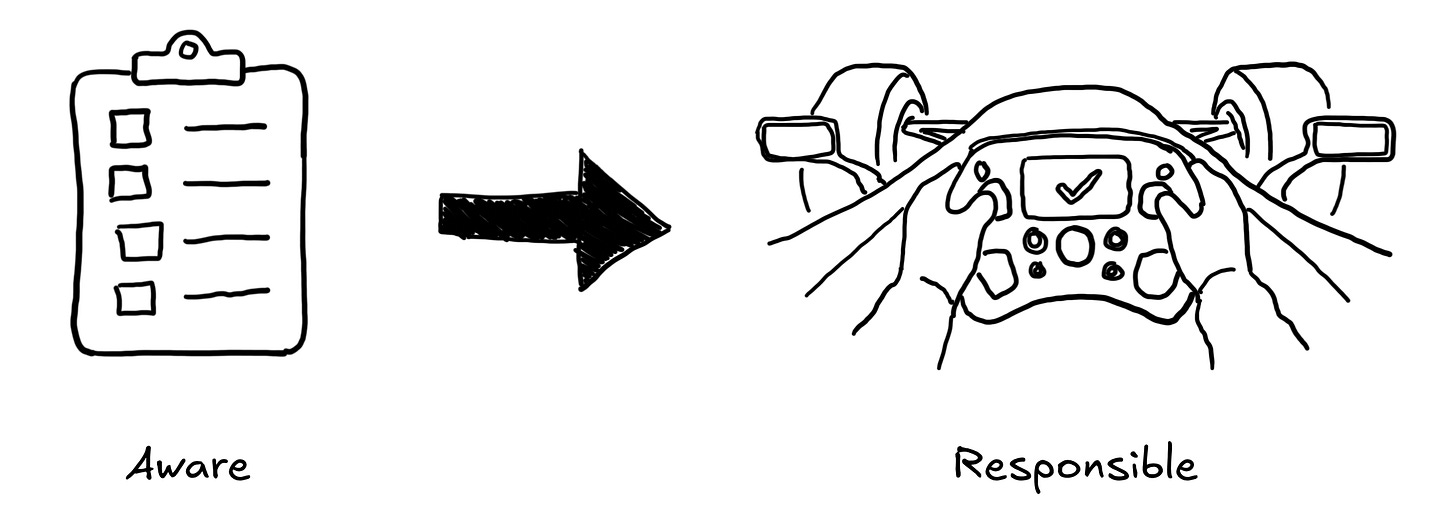

Responsibility only works with authority. You cannot hold someone accountable for driving if they cannot reach the steering wheel. If an owner is on the hook for schedule, they need the ability to change a requirement, swap a vendor, book test time, and spend to clear a blocker. But if you’ve built your culture well, these decisions won’t be made in a vacuum, and the RE will have consulted with the relevant stakeholders and leaders as needed.

Good guardrails keep the culture healthy without slowing it down. Purchase Order approval thresholds ensure large orders don’t go without scrutiny. Design reviews provide checks and balances by documenting decisions and the rationales behind them. Manufacturing Issues and Risk tracking keeps problems visible. Do these well and this individual agency turns from a risk into the engine that pulls the program forward.

Clear ownership collapses decision loops and expedites development

Outcomes, not process or specifications, define success. The leanest process that still burns down risk is the right one, and a single accountable owner is the shortest path to that balance. Hopefully, the examples above gave you some insight into the benefits of operating this way and what real responsibility looks like. Of course, there are drawbacks, but the benefits far outweigh them. The RE idea is not a slogan. It is an operating system for speed and ambition.

If you’re interested in learning how to start transitioning your organization into a RE-minded culture, then stay tuned. We’ll be releasing a series of articles tackling this step by step.

The Responsible Engineer

The ownership culture behind SpaceX’s rapid development, and how hardware startups can apply it.

TL;DR: In startups chasing faster development, there is plenty of folklore about velocity, vertical integration, long hours, decisive CEOs, and big fundraising. But what truly enables high-velocity execution? We look at the engineering ethos behind a company whose culture has been studied, mythologized, and imitated across the industry: SpaceX. At its core is the concept of the Responsible Engineer: a framework where one owner is accountable for an outcome rather than a task list, and has the authority to make the decisions that turn it into reality. Without this ground-up mentality of true responsibility and extreme ownership, rapid development will always struggle.

The Responsible Engineer (RE) is responsible for an outcome. This means wearing many hats to get there.

Let’s talk about “Responsibility”

When leading teams, there is always talk about accountability and responsibility. In big companies, the RACI chart is the common language. One person is Responsible, another is Accountable, many are Consulted, and many are Informed. In practice the weight often shifts to the C and the I, which slows decisions and thins real ownership. Most of the time, unless you’re referring to V.P. level leadership, people talk about responsibility as the responsibility to accomplish a set of tasks and not the responsibility of delivering an outcome.

Take a more traditional aerospace organization example: A systems engineer might be responsible for establishing the requirements for a component, a domain specific engineer might be responsible for providing the overall design, a designer might responsible for the final CAD, an analyst responsible for providing margins, a scheduler might be responsible for the schedule, a program manager responsible for tracking costs and progress, a manufacturing engineer responsible for fabrication, and a test engineer responsible for validating the part. Maybe that’s a bit extreme, but I’m sure you have all seen similar scenarios. But who is accountable? “Responsibility” has been reduced to the narrow definition of “who completed the task”1. The why, how, and when something is done is delegated to others.

This engineering operational paradigm has seen humanity accomplish amazing engineering feats like landing rovers on Mars, putting the International Space Station in orbit, and flying the behemoth Airbus A380 passenger jet across the Atlantic. Operating like this also offers a certain organizational robustness to personnel risk, as losing a single person in that chain of responsibilities is unlikely to derail a program. Engineers are more replaceable when they take on bite-sized task-based “responsibilities.”

But this approach is not without its downsides, especially when operating in a startup environment. The number of people increases, communication is slower, objectives become obfuscated, and decisions are harder to make. But most importantly, where does the ownership lie? Who is ultimately responsible for the success of the component and how that component plays into the success of the overall project, mission or company? Engineers operating in this paradigm are often aware of outcomes, but not responsible for them.

Startups are forced to establish product market fit, demonstrate viability, and beat the incumbents all before their cash runs out. And here’s where the strength of the Responsible Engineer (RE) mindset comes into play.

Getting through tasks or taking the wheel.

When we talk about the Responsible Engineer, what we’re really talking about is ownership.

The Responsible Engineer (or RE) framework is one employed religiously at SpaceX. It is the core operating system that allowed a relatively small, scrappy team to build and fly rockets and spacecraft faster than anyone thought possible. It’s hard-wired into the culture, even to this day.

What outcome does your hardware or software provide? You own making the required functionality work. You own schedule. You own the resources you need. You own your interfaces. You own requirements for yourself and for partners. You own your budget. As an RE you are a mini systems engineer, an analyst, a designer, a test lead, and a program manager. In the RACI parlance, “ownership” is the combination of R&A. RE’s own their outcomes.

Depending on the scope, you will get support, and you might even lead a team. But the ultimate responsibility for success and the definition of success sit with a single person. And you have sufficient agency to make the decisions that need to be made.

When responsibility is clear and consolidated, things move faster. Incentives line up because instead of trying to complete your task, you’re trying to make the decision that results in the best overall outcome. People know who handles what, and blockers get chased because they are not someone else’s problem. Designs can iterate quicker because information flows sideways through the company in real time, not up a ladder and back down through many hands.

Example: the design cycle for a valve

As mentioned before, in a traditional setup you might have a systems engineer who gathers inputs and writes a spec, a mechanical engineer who designs, a designer who drafts, a stress analyst who produces margins, a manufacturing engineer who places orders, a test engineer who runs development testing, and a program manager who watches schedule and cost. They are all capable, but each carries a narrow view and very little accountability for the full outcome. The program manager is asked to deliver the valve yet is 100% reliant on what everyone else reports.

Let’s compare how operating with the RE mindset might be different than the Aware Engineer mindset.

A valve… the bane of all space programs

Technical correctness versus pragmatism

The Aware Engineer might be given a swath of conservative requirements from the systems engineer, and so they start sourcing a flight-qualified solenoid actuator from a top-tier vendor. It's rated for deep space, has perfect documentation, and meets every heritage requirement. It’s the safe, technically correct choice. But it comes with a 40-week lead time and a big price tag, and it’s nearly impossible to tweak once it’s ordered.

Now let’s put on the RE hat. Their job is to deliver a working valve, fast. Because they understand how the valve is used in the system, they know the actuator only needs to fire a handful of times. They understand the thermal margins, the limited duty cycle, and the fact that they can validate performance through direct testing. So they find a small domestic coil shop that’s never flown in space but can build to spec and deliver in three weeks. The potting material the shop usually uses needs to be changed to something more space-worthy, but they are happy to give it a go. It’s not textbook perfect, but it’s testable, it’s cheap, and it gets hardware on the bench fast.

Highlighting risk vs. closing risk

The latest round of analysis leading up to a critical test show vibration levels higher than before. The Aware Engineer, sees this and is concerned that it might cause the valve to chatter, putting the mission at risk during this time. The risk is logged and tracked. Everyone waits for a review to decide what to do next.

With the RE hat on, the engineer goes and talks to the dynamics team. Are they sure this is right? Is there anything that can be done to sharpen the pencil and bring down the predicted levels? Unfortunately, they strike out, no luck there, and the levels are the best they have. There’s no time to redesign anything. They know they are delivering the outcome of a successful flight, not just a component. So they talk to the software person who has been handling the actuation of the valve, and agree on a simple re-assert strategy that continually commands the valve open during this short high vibe period. The risk is logged and tracked, but the mitigation is now done, so it’s closed and accepted.

Broadcasting schedule delays vs. managing schedule delays and challenging requirements.

Now the valve is four weeks late and pushing the whole program. A set of meetings appears. What can we do? The manufacturing engineer calls other shops. Lead times match or get worse. The test engineer is asked to shorten the test cycle. They shave a week, maybe. In truth, the schedule was already optimistic, and the change is just schedule accordion. Time compresses on paper and then springs back in reality. In the end, the program slips.

No single person had both the incentive and the cross-functional knowledge to bring the valve back on track. Responsibility was diffuse and incentives misaligned. A real solution was never likely.

As a RE, the owner has been talking with the machine shop about their schedule. Because they have an end-to-end view, the authority to act, and a real incentive to finish on time, they see the real driver. The leak rate target forced a tolerance that only a specialty shop could hold, which blew out lead time. They call the engineer who owns the interface that pushed the leak rate target. That engineer admits there is some pocket margin they can give back and open up the requirement a bit. With that, the engineer loosens a tolerance, moves the work to a faster shop, and pulls in the date. It takes two conversations and one decision.

Responsibilities are more like gaussian curves than rectangular functions. Overlap is part of the operating paradigm.

But wait — it can’t all be good, right?

In a traditional organization, when responsibilities overlap, teams lean on role boundaries and formal escalation. That keeps order, yet it often adds delay. Conflicts simmer until program reviews, things are ignored as being “not my problem,” and people hedge designs to protect their function. Junior engineers stay in their swim lanes and do not get chances to build the judgment the company needs.

A team operating with the Responsible mindset can feel like the inmates are running the asylum. Responsibilities will overlap. Some overlaps resolve quickly, some need mediation, and some can turn toxic. Without task boundaries, an engineer can head down the wrong path or over-optimize for a self-serving design.

This is where strong leadership matters. Running a team of REs is not set and forget. Leaders have to trust their engineers and accept that there will be friction and mistakes. They clarify direction and why it matters, and they provide the scaffolding for sound decisions. They unblock when needed and let teams work it out everywhere else. They need to have earned the trust of their engineers by being the fastest fair escalation path, making crisp calls, taking the heat, and giving credit down, so engineers come to them when an issue is intractable or crosses a threshold and needs a quick decision.

Responsibility only works with authority. You cannot hold someone accountable for driving if they cannot reach the steering wheel. If an owner is on the hook for schedule, they need the ability to change a requirement, swap a vendor, book test time, and spend to clear a blocker. But if you’ve built your culture well, these decisions won’t be made in a vacuum, and the RE will have consulted with the relevant stakeholders and leaders as needed.

Good guardrails keep the culture healthy without slowing it down. Purchase Order approval thresholds ensure large orders don’t go without scrutiny. Design reviews provide checks and balances by documenting decisions and the rationales behind them. Manufacturing Issues and Risk tracking keeps problems visible. Do these well and this individual agency turns from a risk into the engine that pulls the program forward.

Clear ownership collapses decision loops and expedites development

Outcomes, not process or specifications, define success. The leanest process that still burns down risk is the right one, and a single accountable owner is the shortest path to that balance. Hopefully, the examples above gave you some insight into the benefits of operating this way and what real responsibility looks like. Of course, there are drawbacks, but the benefits far outweigh them. The RE idea is not a slogan. It is an operating system for speed and ambition.

If you’re interested in learning how to start transitioning your organization into a RE-minded culture, then stay tuned. We’ll be releasing a series of articles tackling this step by step.

The Responsible Engineer

The ownership culture behind SpaceX’s rapid development, and how hardware startups can apply it.

TL;DR: In startups chasing faster development, there is plenty of folklore about velocity, vertical integration, long hours, decisive CEOs, and big fundraising. But what truly enables high-velocity execution? We look at the engineering ethos behind a company whose culture has been studied, mythologized, and imitated across the industry: SpaceX. At its core is the concept of the Responsible Engineer: a framework where one owner is accountable for an outcome rather than a task list, and has the authority to make the decisions that turn it into reality. Without this ground-up mentality of true responsibility and extreme ownership, rapid development will always struggle.

The Responsible Engineer (RE) is responsible for an outcome. This means wearing many hats to get there.

Let’s talk about “Responsibility”

When leading teams, there is always talk about accountability and responsibility. In big companies, the RACI chart is the common language. One person is Responsible, another is Accountable, many are Consulted, and many are Informed. In practice the weight often shifts to the C and the I, which slows decisions and thins real ownership. Most of the time, unless you’re referring to V.P. level leadership, people talk about responsibility as the responsibility to accomplish a set of tasks and not the responsibility of delivering an outcome.

Take a more traditional aerospace organization example: A systems engineer might be responsible for establishing the requirements for a component, a domain specific engineer might be responsible for providing the overall design, a designer might responsible for the final CAD, an analyst responsible for providing margins, a scheduler might be responsible for the schedule, a program manager responsible for tracking costs and progress, a manufacturing engineer responsible for fabrication, and a test engineer responsible for validating the part. Maybe that’s a bit extreme, but I’m sure you have all seen similar scenarios. But who is accountable? “Responsibility” has been reduced to the narrow definition of “who completed the task”1. The why, how, and when something is done is delegated to others.

This engineering operational paradigm has seen humanity accomplish amazing engineering feats like landing rovers on Mars, putting the International Space Station in orbit, and flying the behemoth Airbus A380 passenger jet across the Atlantic. Operating like this also offers a certain organizational robustness to personnel risk, as losing a single person in that chain of responsibilities is unlikely to derail a program. Engineers are more replaceable when they take on bite-sized task-based “responsibilities.”

But this approach is not without its downsides, especially when operating in a startup environment. The number of people increases, communication is slower, objectives become obfuscated, and decisions are harder to make. But most importantly, where does the ownership lie? Who is ultimately responsible for the success of the component and how that component plays into the success of the overall project, mission or company? Engineers operating in this paradigm are often aware of outcomes, but not responsible for them.

Startups are forced to establish product market fit, demonstrate viability, and beat the incumbents all before their cash runs out. And here’s where the strength of the Responsible Engineer (RE) mindset comes into play.

Getting through tasks or taking the wheel.

When we talk about the Responsible Engineer, what we’re really talking about is ownership.

The Responsible Engineer (or RE) framework is one employed religiously at SpaceX. It is the core operating system that allowed a relatively small, scrappy team to build and fly rockets and spacecraft faster than anyone thought possible. It’s hard-wired into the culture, even to this day.

What outcome does your hardware or software provide? You own making the required functionality work. You own schedule. You own the resources you need. You own your interfaces. You own requirements for yourself and for partners. You own your budget. As an RE you are a mini systems engineer, an analyst, a designer, a test lead, and a program manager. In the RACI parlance, “ownership” is the combination of R&A. RE’s own their outcomes.

Depending on the scope, you will get support, and you might even lead a team. But the ultimate responsibility for success and the definition of success sit with a single person. And you have sufficient agency to make the decisions that need to be made.

When responsibility is clear and consolidated, things move faster. Incentives line up because instead of trying to complete your task, you’re trying to make the decision that results in the best overall outcome. People know who handles what, and blockers get chased because they are not someone else’s problem. Designs can iterate quicker because information flows sideways through the company in real time, not up a ladder and back down through many hands.

Example: the design cycle for a valve

As mentioned before, in a traditional setup you might have a systems engineer who gathers inputs and writes a spec, a mechanical engineer who designs, a designer who drafts, a stress analyst who produces margins, a manufacturing engineer who places orders, a test engineer who runs development testing, and a program manager who watches schedule and cost. They are all capable, but each carries a narrow view and very little accountability for the full outcome. The program manager is asked to deliver the valve yet is 100% reliant on what everyone else reports.

Let’s compare how operating with the RE mindset might be different than the Aware Engineer mindset.

A valve… the bane of all space programs

Technical correctness versus pragmatism

The Aware Engineer might be given a swath of conservative requirements from the systems engineer, and so they start sourcing a flight-qualified solenoid actuator from a top-tier vendor. It's rated for deep space, has perfect documentation, and meets every heritage requirement. It’s the safe, technically correct choice. But it comes with a 40-week lead time and a big price tag, and it’s nearly impossible to tweak once it’s ordered.

Now let’s put on the RE hat. Their job is to deliver a working valve, fast. Because they understand how the valve is used in the system, they know the actuator only needs to fire a handful of times. They understand the thermal margins, the limited duty cycle, and the fact that they can validate performance through direct testing. So they find a small domestic coil shop that’s never flown in space but can build to spec and deliver in three weeks. The potting material the shop usually uses needs to be changed to something more space-worthy, but they are happy to give it a go. It’s not textbook perfect, but it’s testable, it’s cheap, and it gets hardware on the bench fast.

Highlighting risk vs. closing risk

The latest round of analysis leading up to a critical test show vibration levels higher than before. The Aware Engineer, sees this and is concerned that it might cause the valve to chatter, putting the mission at risk during this time. The risk is logged and tracked. Everyone waits for a review to decide what to do next.

With the RE hat on, the engineer goes and talks to the dynamics team. Are they sure this is right? Is there anything that can be done to sharpen the pencil and bring down the predicted levels? Unfortunately, they strike out, no luck there, and the levels are the best they have. There’s no time to redesign anything. They know they are delivering the outcome of a successful flight, not just a component. So they talk to the software person who has been handling the actuation of the valve, and agree on a simple re-assert strategy that continually commands the valve open during this short high vibe period. The risk is logged and tracked, but the mitigation is now done, so it’s closed and accepted.

Broadcasting schedule delays vs. managing schedule delays and challenging requirements.

Now the valve is four weeks late and pushing the whole program. A set of meetings appears. What can we do? The manufacturing engineer calls other shops. Lead times match or get worse. The test engineer is asked to shorten the test cycle. They shave a week, maybe. In truth, the schedule was already optimistic, and the change is just schedule accordion. Time compresses on paper and then springs back in reality. In the end, the program slips.

No single person had both the incentive and the cross-functional knowledge to bring the valve back on track. Responsibility was diffuse and incentives misaligned. A real solution was never likely.

As a RE, the owner has been talking with the machine shop about their schedule. Because they have an end-to-end view, the authority to act, and a real incentive to finish on time, they see the real driver. The leak rate target forced a tolerance that only a specialty shop could hold, which blew out lead time. They call the engineer who owns the interface that pushed the leak rate target. That engineer admits there is some pocket margin they can give back and open up the requirement a bit. With that, the engineer loosens a tolerance, moves the work to a faster shop, and pulls in the date. It takes two conversations and one decision.

Responsibilities are more like gaussian curves than rectangular functions. Overlap is part of the operating paradigm.

But wait — it can’t all be good, right?

In a traditional organization, when responsibilities overlap, teams lean on role boundaries and formal escalation. That keeps order, yet it often adds delay. Conflicts simmer until program reviews, things are ignored as being “not my problem,” and people hedge designs to protect their function. Junior engineers stay in their swim lanes and do not get chances to build the judgment the company needs.

A team operating with the Responsible mindset can feel like the inmates are running the asylum. Responsibilities will overlap. Some overlaps resolve quickly, some need mediation, and some can turn toxic. Without task boundaries, an engineer can head down the wrong path or over-optimize for a self-serving design.

This is where strong leadership matters. Running a team of REs is not set and forget. Leaders have to trust their engineers and accept that there will be friction and mistakes. They clarify direction and why it matters, and they provide the scaffolding for sound decisions. They unblock when needed and let teams work it out everywhere else. They need to have earned the trust of their engineers by being the fastest fair escalation path, making crisp calls, taking the heat, and giving credit down, so engineers come to them when an issue is intractable or crosses a threshold and needs a quick decision.

Responsibility only works with authority. You cannot hold someone accountable for driving if they cannot reach the steering wheel. If an owner is on the hook for schedule, they need the ability to change a requirement, swap a vendor, book test time, and spend to clear a blocker. But if you’ve built your culture well, these decisions won’t be made in a vacuum, and the RE will have consulted with the relevant stakeholders and leaders as needed.

Good guardrails keep the culture healthy without slowing it down. Purchase Order approval thresholds ensure large orders don’t go without scrutiny. Design reviews provide checks and balances by documenting decisions and the rationales behind them. Manufacturing Issues and Risk tracking keeps problems visible. Do these well and this individual agency turns from a risk into the engine that pulls the program forward.

Clear ownership collapses decision loops and expedites development

Outcomes, not process or specifications, define success. The leanest process that still burns down risk is the right one, and a single accountable owner is the shortest path to that balance. Hopefully, the examples above gave you some insight into the benefits of operating this way and what real responsibility looks like. Of course, there are drawbacks, but the benefits far outweigh them. The RE idea is not a slogan. It is an operating system for speed and ambition.

If you’re interested in learning how to start transitioning your organization into a RE-minded culture, then stay tuned. We’ll be releasing a series of articles tackling this step by step.

The Responsible Engineer

The ownership culture behind SpaceX’s rapid development, and how hardware startups can apply it.

TL;DR: In startups chasing faster development, there is plenty of folklore about velocity, vertical integration, long hours, decisive CEOs, and big fundraising. But what truly enables high-velocity execution? We look at the engineering ethos behind a company whose culture has been studied, mythologized, and imitated across the industry: SpaceX. At its core is the concept of the Responsible Engineer: a framework where one owner is accountable for an outcome rather than a task list, and has the authority to make the decisions that turn it into reality. Without this ground-up mentality of true responsibility and extreme ownership, rapid development will always struggle.

The Responsible Engineer (RE) is responsible for an outcome. This means wearing many hats to get there.

Let’s talk about “Responsibility”

When leading teams, there is always talk about accountability and responsibility. In big companies, the RACI chart is the common language. One person is Responsible, another is Accountable, many are Consulted, and many are Informed. In practice the weight often shifts to the C and the I, which slows decisions and thins real ownership. Most of the time, unless you’re referring to V.P. level leadership, people talk about responsibility as the responsibility to accomplish a set of tasks and not the responsibility of delivering an outcome.

Take a more traditional aerospace organization example: A systems engineer might be responsible for establishing the requirements for a component, a domain specific engineer might be responsible for providing the overall design, a designer might responsible for the final CAD, an analyst responsible for providing margins, a scheduler might be responsible for the schedule, a program manager responsible for tracking costs and progress, a manufacturing engineer responsible for fabrication, and a test engineer responsible for validating the part. Maybe that’s a bit extreme, but I’m sure you have all seen similar scenarios. But who is accountable? “Responsibility” has been reduced to the narrow definition of “who completed the task”1. The why, how, and when something is done is delegated to others.

This engineering operational paradigm has seen humanity accomplish amazing engineering feats like landing rovers on Mars, putting the International Space Station in orbit, and flying the behemoth Airbus A380 passenger jet across the Atlantic. Operating like this also offers a certain organizational robustness to personnel risk, as losing a single person in that chain of responsibilities is unlikely to derail a program. Engineers are more replaceable when they take on bite-sized task-based “responsibilities.”

But this approach is not without its downsides, especially when operating in a startup environment. The number of people increases, communication is slower, objectives become obfuscated, and decisions are harder to make. But most importantly, where does the ownership lie? Who is ultimately responsible for the success of the component and how that component plays into the success of the overall project, mission or company? Engineers operating in this paradigm are often aware of outcomes, but not responsible for them.

Startups are forced to establish product market fit, demonstrate viability, and beat the incumbents all before their cash runs out. And here’s where the strength of the Responsible Engineer (RE) mindset comes into play.

Getting through tasks or taking the wheel.

When we talk about the Responsible Engineer, what we’re really talking about is ownership.

The Responsible Engineer (or RE) framework is one employed religiously at SpaceX. It is the core operating system that allowed a relatively small, scrappy team to build and fly rockets and spacecraft faster than anyone thought possible. It’s hard-wired into the culture, even to this day.

What outcome does your hardware or software provide? You own making the required functionality work. You own schedule. You own the resources you need. You own your interfaces. You own requirements for yourself and for partners. You own your budget. As an RE you are a mini systems engineer, an analyst, a designer, a test lead, and a program manager. In the RACI parlance, “ownership” is the combination of R&A. RE’s own their outcomes.

Depending on the scope, you will get support, and you might even lead a team. But the ultimate responsibility for success and the definition of success sit with a single person. And you have sufficient agency to make the decisions that need to be made.

When responsibility is clear and consolidated, things move faster. Incentives line up because instead of trying to complete your task, you’re trying to make the decision that results in the best overall outcome. People know who handles what, and blockers get chased because they are not someone else’s problem. Designs can iterate quicker because information flows sideways through the company in real time, not up a ladder and back down through many hands.

Example: the design cycle for a valve

As mentioned before, in a traditional setup you might have a systems engineer who gathers inputs and writes a spec, a mechanical engineer who designs, a designer who drafts, a stress analyst who produces margins, a manufacturing engineer who places orders, a test engineer who runs development testing, and a program manager who watches schedule and cost. They are all capable, but each carries a narrow view and very little accountability for the full outcome. The program manager is asked to deliver the valve yet is 100% reliant on what everyone else reports.

Let’s compare how operating with the RE mindset might be different than the Aware Engineer mindset.

A valve… the bane of all space programs

Technical correctness versus pragmatism

The Aware Engineer might be given a swath of conservative requirements from the systems engineer, and so they start sourcing a flight-qualified solenoid actuator from a top-tier vendor. It's rated for deep space, has perfect documentation, and meets every heritage requirement. It’s the safe, technically correct choice. But it comes with a 40-week lead time and a big price tag, and it’s nearly impossible to tweak once it’s ordered.

Now let’s put on the RE hat. Their job is to deliver a working valve, fast. Because they understand how the valve is used in the system, they know the actuator only needs to fire a handful of times. They understand the thermal margins, the limited duty cycle, and the fact that they can validate performance through direct testing. So they find a small domestic coil shop that’s never flown in space but can build to spec and deliver in three weeks. The potting material the shop usually uses needs to be changed to something more space-worthy, but they are happy to give it a go. It’s not textbook perfect, but it’s testable, it’s cheap, and it gets hardware on the bench fast.

Highlighting risk vs. closing risk

The latest round of analysis leading up to a critical test show vibration levels higher than before. The Aware Engineer, sees this and is concerned that it might cause the valve to chatter, putting the mission at risk during this time. The risk is logged and tracked. Everyone waits for a review to decide what to do next.

With the RE hat on, the engineer goes and talks to the dynamics team. Are they sure this is right? Is there anything that can be done to sharpen the pencil and bring down the predicted levels? Unfortunately, they strike out, no luck there, and the levels are the best they have. There’s no time to redesign anything. They know they are delivering the outcome of a successful flight, not just a component. So they talk to the software person who has been handling the actuation of the valve, and agree on a simple re-assert strategy that continually commands the valve open during this short high vibe period. The risk is logged and tracked, but the mitigation is now done, so it’s closed and accepted.

Broadcasting schedule delays vs. managing schedule delays and challenging requirements.

Now the valve is four weeks late and pushing the whole program. A set of meetings appears. What can we do? The manufacturing engineer calls other shops. Lead times match or get worse. The test engineer is asked to shorten the test cycle. They shave a week, maybe. In truth, the schedule was already optimistic, and the change is just schedule accordion. Time compresses on paper and then springs back in reality. In the end, the program slips.

No single person had both the incentive and the cross-functional knowledge to bring the valve back on track. Responsibility was diffuse and incentives misaligned. A real solution was never likely.

As a RE, the owner has been talking with the machine shop about their schedule. Because they have an end-to-end view, the authority to act, and a real incentive to finish on time, they see the real driver. The leak rate target forced a tolerance that only a specialty shop could hold, which blew out lead time. They call the engineer who owns the interface that pushed the leak rate target. That engineer admits there is some pocket margin they can give back and open up the requirement a bit. With that, the engineer loosens a tolerance, moves the work to a faster shop, and pulls in the date. It takes two conversations and one decision.

Responsibilities are more like gaussian curves than rectangular functions. Overlap is part of the operating paradigm.

But wait — it can’t all be good, right?

In a traditional organization, when responsibilities overlap, teams lean on role boundaries and formal escalation. That keeps order, yet it often adds delay. Conflicts simmer until program reviews, things are ignored as being “not my problem,” and people hedge designs to protect their function. Junior engineers stay in their swim lanes and do not get chances to build the judgment the company needs.

A team operating with the Responsible mindset can feel like the inmates are running the asylum. Responsibilities will overlap. Some overlaps resolve quickly, some need mediation, and some can turn toxic. Without task boundaries, an engineer can head down the wrong path or over-optimize for a self-serving design.

This is where strong leadership matters. Running a team of REs is not set and forget. Leaders have to trust their engineers and accept that there will be friction and mistakes. They clarify direction and why it matters, and they provide the scaffolding for sound decisions. They unblock when needed and let teams work it out everywhere else. They need to have earned the trust of their engineers by being the fastest fair escalation path, making crisp calls, taking the heat, and giving credit down, so engineers come to them when an issue is intractable or crosses a threshold and needs a quick decision.

Responsibility only works with authority. You cannot hold someone accountable for driving if they cannot reach the steering wheel. If an owner is on the hook for schedule, they need the ability to change a requirement, swap a vendor, book test time, and spend to clear a blocker. But if you’ve built your culture well, these decisions won’t be made in a vacuum, and the RE will have consulted with the relevant stakeholders and leaders as needed.

Good guardrails keep the culture healthy without slowing it down. Purchase Order approval thresholds ensure large orders don’t go without scrutiny. Design reviews provide checks and balances by documenting decisions and the rationales behind them. Manufacturing Issues and Risk tracking keeps problems visible. Do these well and this individual agency turns from a risk into the engine that pulls the program forward.

Clear ownership collapses decision loops and expedites development

Outcomes, not process or specifications, define success. The leanest process that still burns down risk is the right one, and a single accountable owner is the shortest path to that balance. Hopefully, the examples above gave you some insight into the benefits of operating this way and what real responsibility looks like. Of course, there are drawbacks, but the benefits far outweigh them. The RE idea is not a slogan. It is an operating system for speed and ambition.

If you’re interested in learning how to start transitioning your organization into a RE-minded culture, then stay tuned. We’ll be releasing a series of articles tackling this step by step.

The Responsible Engineer

The ownership culture behind SpaceX’s rapid development, and how hardware startups can apply it.

TL;DR: In startups chasing faster development, there is plenty of folklore about velocity, vertical integration, long hours, decisive CEOs, and big fundraising. But what truly enables high-velocity execution? We look at the engineering ethos behind a company whose culture has been studied, mythologized, and imitated across the industry: SpaceX. At its core is the concept of the Responsible Engineer: a framework where one owner is accountable for an outcome rather than a task list, and has the authority to make the decisions that turn it into reality. Without this ground-up mentality of true responsibility and extreme ownership, rapid development will always struggle.

The Responsible Engineer (RE) is responsible for an outcome. This means wearing many hats to get there.

Let’s talk about “Responsibility”

When leading teams, there is always talk about accountability and responsibility. In big companies, the RACI chart is the common language. One person is Responsible, another is Accountable, many are Consulted, and many are Informed. In practice the weight often shifts to the C and the I, which slows decisions and thins real ownership. Most of the time, unless you’re referring to V.P. level leadership, people talk about responsibility as the responsibility to accomplish a set of tasks and not the responsibility of delivering an outcome.

Take a more traditional aerospace organization example: A systems engineer might be responsible for establishing the requirements for a component, a domain specific engineer might be responsible for providing the overall design, a designer might responsible for the final CAD, an analyst responsible for providing margins, a scheduler might be responsible for the schedule, a program manager responsible for tracking costs and progress, a manufacturing engineer responsible for fabrication, and a test engineer responsible for validating the part. Maybe that’s a bit extreme, but I’m sure you have all seen similar scenarios. But who is accountable? “Responsibility” has been reduced to the narrow definition of “who completed the task”1. The why, how, and when something is done is delegated to others.

This engineering operational paradigm has seen humanity accomplish amazing engineering feats like landing rovers on Mars, putting the International Space Station in orbit, and flying the behemoth Airbus A380 passenger jet across the Atlantic. Operating like this also offers a certain organizational robustness to personnel risk, as losing a single person in that chain of responsibilities is unlikely to derail a program. Engineers are more replaceable when they take on bite-sized task-based “responsibilities.”

But this approach is not without its downsides, especially when operating in a startup environment. The number of people increases, communication is slower, objectives become obfuscated, and decisions are harder to make. But most importantly, where does the ownership lie? Who is ultimately responsible for the success of the component and how that component plays into the success of the overall project, mission or company? Engineers operating in this paradigm are often aware of outcomes, but not responsible for them.

Startups are forced to establish product market fit, demonstrate viability, and beat the incumbents all before their cash runs out. And here’s where the strength of the Responsible Engineer (RE) mindset comes into play.

Getting through tasks or taking the wheel.

When we talk about the Responsible Engineer, what we’re really talking about is ownership.

The Responsible Engineer (or RE) framework is one employed religiously at SpaceX. It is the core operating system that allowed a relatively small, scrappy team to build and fly rockets and spacecraft faster than anyone thought possible. It’s hard-wired into the culture, even to this day.

What outcome does your hardware or software provide? You own making the required functionality work. You own schedule. You own the resources you need. You own your interfaces. You own requirements for yourself and for partners. You own your budget. As an RE you are a mini systems engineer, an analyst, a designer, a test lead, and a program manager. In the RACI parlance, “ownership” is the combination of R&A. RE’s own their outcomes.

Depending on the scope, you will get support, and you might even lead a team. But the ultimate responsibility for success and the definition of success sit with a single person. And you have sufficient agency to make the decisions that need to be made.

When responsibility is clear and consolidated, things move faster. Incentives line up because instead of trying to complete your task, you’re trying to make the decision that results in the best overall outcome. People know who handles what, and blockers get chased because they are not someone else’s problem. Designs can iterate quicker because information flows sideways through the company in real time, not up a ladder and back down through many hands.

Example: the design cycle for a valve

As mentioned before, in a traditional setup you might have a systems engineer who gathers inputs and writes a spec, a mechanical engineer who designs, a designer who drafts, a stress analyst who produces margins, a manufacturing engineer who places orders, a test engineer who runs development testing, and a program manager who watches schedule and cost. They are all capable, but each carries a narrow view and very little accountability for the full outcome. The program manager is asked to deliver the valve yet is 100% reliant on what everyone else reports.

Let’s compare how operating with the RE mindset might be different than the Aware Engineer mindset.

A valve… the bane of all space programs

Technical correctness versus pragmatism

The Aware Engineer might be given a swath of conservative requirements from the systems engineer, and so they start sourcing a flight-qualified solenoid actuator from a top-tier vendor. It's rated for deep space, has perfect documentation, and meets every heritage requirement. It’s the safe, technically correct choice. But it comes with a 40-week lead time and a big price tag, and it’s nearly impossible to tweak once it’s ordered.

Now let’s put on the RE hat. Their job is to deliver a working valve, fast. Because they understand how the valve is used in the system, they know the actuator only needs to fire a handful of times. They understand the thermal margins, the limited duty cycle, and the fact that they can validate performance through direct testing. So they find a small domestic coil shop that’s never flown in space but can build to spec and deliver in three weeks. The potting material the shop usually uses needs to be changed to something more space-worthy, but they are happy to give it a go. It’s not textbook perfect, but it’s testable, it’s cheap, and it gets hardware on the bench fast.

Highlighting risk vs. closing risk

The latest round of analysis leading up to a critical test show vibration levels higher than before. The Aware Engineer, sees this and is concerned that it might cause the valve to chatter, putting the mission at risk during this time. The risk is logged and tracked. Everyone waits for a review to decide what to do next.

With the RE hat on, the engineer goes and talks to the dynamics team. Are they sure this is right? Is there anything that can be done to sharpen the pencil and bring down the predicted levels? Unfortunately, they strike out, no luck there, and the levels are the best they have. There’s no time to redesign anything. They know they are delivering the outcome of a successful flight, not just a component. So they talk to the software person who has been handling the actuation of the valve, and agree on a simple re-assert strategy that continually commands the valve open during this short high vibe period. The risk is logged and tracked, but the mitigation is now done, so it’s closed and accepted.

Broadcasting schedule delays vs. managing schedule delays and challenging requirements.

Now the valve is four weeks late and pushing the whole program. A set of meetings appears. What can we do? The manufacturing engineer calls other shops. Lead times match or get worse. The test engineer is asked to shorten the test cycle. They shave a week, maybe. In truth, the schedule was already optimistic, and the change is just schedule accordion. Time compresses on paper and then springs back in reality. In the end, the program slips.

No single person had both the incentive and the cross-functional knowledge to bring the valve back on track. Responsibility was diffuse and incentives misaligned. A real solution was never likely.

As a RE, the owner has been talking with the machine shop about their schedule. Because they have an end-to-end view, the authority to act, and a real incentive to finish on time, they see the real driver. The leak rate target forced a tolerance that only a specialty shop could hold, which blew out lead time. They call the engineer who owns the interface that pushed the leak rate target. That engineer admits there is some pocket margin they can give back and open up the requirement a bit. With that, the engineer loosens a tolerance, moves the work to a faster shop, and pulls in the date. It takes two conversations and one decision.

Responsibilities are more like gaussian curves than rectangular functions. Overlap is part of the operating paradigm.

But wait — it can’t all be good, right?

In a traditional organization, when responsibilities overlap, teams lean on role boundaries and formal escalation. That keeps order, yet it often adds delay. Conflicts simmer until program reviews, things are ignored as being “not my problem,” and people hedge designs to protect their function. Junior engineers stay in their swim lanes and do not get chances to build the judgment the company needs.

A team operating with the Responsible mindset can feel like the inmates are running the asylum. Responsibilities will overlap. Some overlaps resolve quickly, some need mediation, and some can turn toxic. Without task boundaries, an engineer can head down the wrong path or over-optimize for a self-serving design.

This is where strong leadership matters. Running a team of REs is not set and forget. Leaders have to trust their engineers and accept that there will be friction and mistakes. They clarify direction and why it matters, and they provide the scaffolding for sound decisions. They unblock when needed and let teams work it out everywhere else. They need to have earned the trust of their engineers by being the fastest fair escalation path, making crisp calls, taking the heat, and giving credit down, so engineers come to them when an issue is intractable or crosses a threshold and needs a quick decision.

Responsibility only works with authority. You cannot hold someone accountable for driving if they cannot reach the steering wheel. If an owner is on the hook for schedule, they need the ability to change a requirement, swap a vendor, book test time, and spend to clear a blocker. But if you’ve built your culture well, these decisions won’t be made in a vacuum, and the RE will have consulted with the relevant stakeholders and leaders as needed.

Good guardrails keep the culture healthy without slowing it down. Purchase Order approval thresholds ensure large orders don’t go without scrutiny. Design reviews provide checks and balances by documenting decisions and the rationales behind them. Manufacturing Issues and Risk tracking keeps problems visible. Do these well and this individual agency turns from a risk into the engine that pulls the program forward.

Clear ownership collapses decision loops and expedites development

Outcomes, not process or specifications, define success. The leanest process that still burns down risk is the right one, and a single accountable owner is the shortest path to that balance. Hopefully, the examples above gave you some insight into the benefits of operating this way and what real responsibility looks like. Of course, there are drawbacks, but the benefits far outweigh them. The RE idea is not a slogan. It is an operating system for speed and ambition.

If you’re interested in learning how to start transitioning your organization into a RE-minded culture, then stay tuned. We’ll be releasing a series of articles tackling this step by step.

The Responsible Engineer

The ownership culture behind SpaceX’s rapid development, and how hardware startups can apply it.

TL;DR: In startups chasing faster development, there is plenty of folklore about velocity, vertical integration, long hours, decisive CEOs, and big fundraising. But what truly enables high-velocity execution? We look at the engineering ethos behind a company whose culture has been studied, mythologized, and imitated across the industry: SpaceX. At its core is the concept of the Responsible Engineer: a framework where one owner is accountable for an outcome rather than a task list, and has the authority to make the decisions that turn it into reality. Without this ground-up mentality of true responsibility and extreme ownership, rapid development will always struggle.

The Responsible Engineer (RE) is responsible for an outcome. This means wearing many hats to get there.

Let’s talk about “Responsibility”

When leading teams, there is always talk about accountability and responsibility. In big companies, the RACI chart is the common language. One person is Responsible, another is Accountable, many are Consulted, and many are Informed. In practice the weight often shifts to the C and the I, which slows decisions and thins real ownership. Most of the time, unless you’re referring to V.P. level leadership, people talk about responsibility as the responsibility to accomplish a set of tasks and not the responsibility of delivering an outcome.

Take a more traditional aerospace organization example: A systems engineer might be responsible for establishing the requirements for a component, a domain specific engineer might be responsible for providing the overall design, a designer might responsible for the final CAD, an analyst responsible for providing margins, a scheduler might be responsible for the schedule, a program manager responsible for tracking costs and progress, a manufacturing engineer responsible for fabrication, and a test engineer responsible for validating the part. Maybe that’s a bit extreme, but I’m sure you have all seen similar scenarios. But who is accountable? “Responsibility” has been reduced to the narrow definition of “who completed the task”1. The why, how, and when something is done is delegated to others.

This engineering operational paradigm has seen humanity accomplish amazing engineering feats like landing rovers on Mars, putting the International Space Station in orbit, and flying the behemoth Airbus A380 passenger jet across the Atlantic. Operating like this also offers a certain organizational robustness to personnel risk, as losing a single person in that chain of responsibilities is unlikely to derail a program. Engineers are more replaceable when they take on bite-sized task-based “responsibilities.”

But this approach is not without its downsides, especially when operating in a startup environment. The number of people increases, communication is slower, objectives become obfuscated, and decisions are harder to make. But most importantly, where does the ownership lie? Who is ultimately responsible for the success of the component and how that component plays into the success of the overall project, mission or company? Engineers operating in this paradigm are often aware of outcomes, but not responsible for them.

Startups are forced to establish product market fit, demonstrate viability, and beat the incumbents all before their cash runs out. And here’s where the strength of the Responsible Engineer (RE) mindset comes into play.

Getting through tasks or taking the wheel.

When we talk about the Responsible Engineer, what we’re really talking about is ownership.

The Responsible Engineer (or RE) framework is one employed religiously at SpaceX. It is the core operating system that allowed a relatively small, scrappy team to build and fly rockets and spacecraft faster than anyone thought possible. It’s hard-wired into the culture, even to this day.

What outcome does your hardware or software provide? You own making the required functionality work. You own schedule. You own the resources you need. You own your interfaces. You own requirements for yourself and for partners. You own your budget. As an RE you are a mini systems engineer, an analyst, a designer, a test lead, and a program manager. In the RACI parlance, “ownership” is the combination of R&A. RE’s own their outcomes.

Depending on the scope, you will get support, and you might even lead a team. But the ultimate responsibility for success and the definition of success sit with a single person. And you have sufficient agency to make the decisions that need to be made.

When responsibility is clear and consolidated, things move faster. Incentives line up because instead of trying to complete your task, you’re trying to make the decision that results in the best overall outcome. People know who handles what, and blockers get chased because they are not someone else’s problem. Designs can iterate quicker because information flows sideways through the company in real time, not up a ladder and back down through many hands.

Example: the design cycle for a valve

As mentioned before, in a traditional setup you might have a systems engineer who gathers inputs and writes a spec, a mechanical engineer who designs, a designer who drafts, a stress analyst who produces margins, a manufacturing engineer who places orders, a test engineer who runs development testing, and a program manager who watches schedule and cost. They are all capable, but each carries a narrow view and very little accountability for the full outcome. The program manager is asked to deliver the valve yet is 100% reliant on what everyone else reports.

Let’s compare how operating with the RE mindset might be different than the Aware Engineer mindset.

A valve… the bane of all space programs

Technical correctness versus pragmatism

The Aware Engineer might be given a swath of conservative requirements from the systems engineer, and so they start sourcing a flight-qualified solenoid actuator from a top-tier vendor. It's rated for deep space, has perfect documentation, and meets every heritage requirement. It’s the safe, technically correct choice. But it comes with a 40-week lead time and a big price tag, and it’s nearly impossible to tweak once it’s ordered.

Now let’s put on the RE hat. Their job is to deliver a working valve, fast. Because they understand how the valve is used in the system, they know the actuator only needs to fire a handful of times. They understand the thermal margins, the limited duty cycle, and the fact that they can validate performance through direct testing. So they find a small domestic coil shop that’s never flown in space but can build to spec and deliver in three weeks. The potting material the shop usually uses needs to be changed to something more space-worthy, but they are happy to give it a go. It’s not textbook perfect, but it’s testable, it’s cheap, and it gets hardware on the bench fast.

Highlighting risk vs. closing risk

The latest round of analysis leading up to a critical test show vibration levels higher than before. The Aware Engineer, sees this and is concerned that it might cause the valve to chatter, putting the mission at risk during this time. The risk is logged and tracked. Everyone waits for a review to decide what to do next.

With the RE hat on, the engineer goes and talks to the dynamics team. Are they sure this is right? Is there anything that can be done to sharpen the pencil and bring down the predicted levels? Unfortunately, they strike out, no luck there, and the levels are the best they have. There’s no time to redesign anything. They know they are delivering the outcome of a successful flight, not just a component. So they talk to the software person who has been handling the actuation of the valve, and agree on a simple re-assert strategy that continually commands the valve open during this short high vibe period. The risk is logged and tracked, but the mitigation is now done, so it’s closed and accepted.

Broadcasting schedule delays vs. managing schedule delays and challenging requirements.

Now the valve is four weeks late and pushing the whole program. A set of meetings appears. What can we do? The manufacturing engineer calls other shops. Lead times match or get worse. The test engineer is asked to shorten the test cycle. They shave a week, maybe. In truth, the schedule was already optimistic, and the change is just schedule accordion. Time compresses on paper and then springs back in reality. In the end, the program slips.

No single person had both the incentive and the cross-functional knowledge to bring the valve back on track. Responsibility was diffuse and incentives misaligned. A real solution was never likely.

As a RE, the owner has been talking with the machine shop about their schedule. Because they have an end-to-end view, the authority to act, and a real incentive to finish on time, they see the real driver. The leak rate target forced a tolerance that only a specialty shop could hold, which blew out lead time. They call the engineer who owns the interface that pushed the leak rate target. That engineer admits there is some pocket margin they can give back and open up the requirement a bit. With that, the engineer loosens a tolerance, moves the work to a faster shop, and pulls in the date. It takes two conversations and one decision.

Responsibilities are more like gaussian curves than rectangular functions. Overlap is part of the operating paradigm.

But wait — it can’t all be good, right?

In a traditional organization, when responsibilities overlap, teams lean on role boundaries and formal escalation. That keeps order, yet it often adds delay. Conflicts simmer until program reviews, things are ignored as being “not my problem,” and people hedge designs to protect their function. Junior engineers stay in their swim lanes and do not get chances to build the judgment the company needs.

A team operating with the Responsible mindset can feel like the inmates are running the asylum. Responsibilities will overlap. Some overlaps resolve quickly, some need mediation, and some can turn toxic. Without task boundaries, an engineer can head down the wrong path or over-optimize for a self-serving design.

This is where strong leadership matters. Running a team of REs is not set and forget. Leaders have to trust their engineers and accept that there will be friction and mistakes. They clarify direction and why it matters, and they provide the scaffolding for sound decisions. They unblock when needed and let teams work it out everywhere else. They need to have earned the trust of their engineers by being the fastest fair escalation path, making crisp calls, taking the heat, and giving credit down, so engineers come to them when an issue is intractable or crosses a threshold and needs a quick decision.

Responsibility only works with authority. You cannot hold someone accountable for driving if they cannot reach the steering wheel. If an owner is on the hook for schedule, they need the ability to change a requirement, swap a vendor, book test time, and spend to clear a blocker. But if you’ve built your culture well, these decisions won’t be made in a vacuum, and the RE will have consulted with the relevant stakeholders and leaders as needed.

Good guardrails keep the culture healthy without slowing it down. Purchase Order approval thresholds ensure large orders don’t go without scrutiny. Design reviews provide checks and balances by documenting decisions and the rationales behind them. Manufacturing Issues and Risk tracking keeps problems visible. Do these well and this individual agency turns from a risk into the engine that pulls the program forward.

Clear ownership collapses decision loops and expedites development

Outcomes, not process or specifications, define success. The leanest process that still burns down risk is the right one, and a single accountable owner is the shortest path to that balance. Hopefully, the examples above gave you some insight into the benefits of operating this way and what real responsibility looks like. Of course, there are drawbacks, but the benefits far outweigh them. The RE idea is not a slogan. It is an operating system for speed and ambition.

If you’re interested in learning how to start transitioning your organization into a RE-minded culture, then stay tuned. We’ll be releasing a series of articles tackling this step by step.